With TJ Byers

Contact Resistance Revealed

Question:

How do I test the condition of the contacts of a 24-volt, 30-amp, sealed relay?

Dixie D.

via Internet

Answer:

There are several methods used to test the integrity and performance of relay contacts. When a relay is energized, a set of bifurcated contacts are shoved against each other. This completes the electrical circuit.

Unfortunately, it’s not that simple. When the contacts first meet each other, they bounce apart, connect again, bounce again, connect, bounce ... and finally come to rest against each other. The amount of time it takes for the contacts to settle down is called, aptly enough, the settling time. This is generally measured on an oscilloscope. Settling times typically range between two and 15 milliseconds (mS).

This is all well and good, but I have a feeling you’re probably more interested in the contact resistance once the bouncing has stopped, as each bounce wears away some of the contact material.

Contact resistance for a new relay ranges from less than 50 milohms to 100 milohms. At 30 amps that can be anywhere from 1.5 to three volts lost across the contacts, which is substantial at 12 volts.

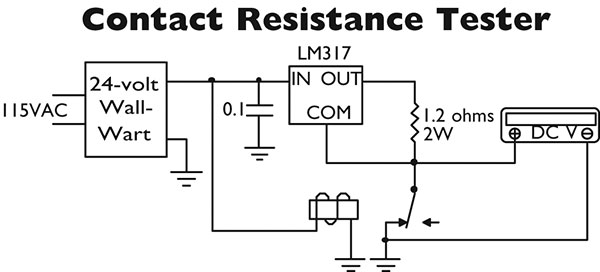

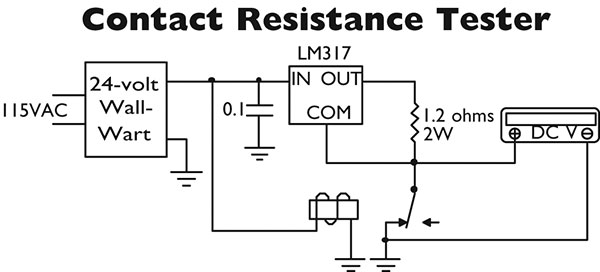

As the relay ages, the contacts become pitted and the resistance increases. The best way to measure contact resistance is with a regulated power supply and a DMM, as shown below.

The LM317 regulator is wired to output a constant current of one amp. The DMM measures the voltage across the contacts and translates it into milohms, where one millivolt equals one milohm. Typically, the meter should read 100 millivolts (mV) or less.

I’d build the circuit above in a plastic utility case with an aluminum cover, to which I’d mount the LM317 and use it as a heatsink. Mount the binding posts on the opposite side of the case; mount the wall wart socket on one of the ends for quick disconnect. The shielded wire “test probes” are made from shielded audio thin-cable. Note that the shield is part of the sensor return to the DMM.

The metal-film, two-watt resistor is probably available only in a five percent tolerance, which is close enough for all but the most demanding measurements. Be aware that the wall wart is specified for a 24-volt coil. To test a 12-volt relay, replace the wall wart with a suitable 12-volt DC unit. Nothing changes with the electronics or calibration.

Comments