I would like to build an inexpensive AC power supply for my workbench. I want something much smaller and lighter than a variac, 0-30 VAC, and maybe one or two amps would be fine. Can anyone point to a good schematic or even a well-written circuit description?

#05201

Jeff Bowles

Columbus, OH

Please log in to post an answer.

Answers

You asked for help on an AC power supply, but without more details it can only be quite general.

Understand that a ‘Powerstat’, ‘Variac’ or similar device DOES NOT provide power line isolation since it is not a true transformer, with isolated windings. A non-isolated power supply on a workbench is as hazardous as the incoming line so if you need that isolation, get a unit that offers isolation, or, add an additional transformer for safety.

Should you be looking for a less expensive or smaller alternative to a ‘Variac’ then consider using a common lamp dimmer in the incoming power line to the transformer! Yes, I know, there’s going to be a slew of nay-sayers about this but, it works! If your load does not depend on the power line waveform for timing accuracy or speed; If your powered device can accommodate the chopped waveform from the triac lamp dimmer; if you don’t exceed the dimmer’s rating with a big starting load, like a motor. Yes, it’s a lot of if’s, but again, it works. I have repaired dozens of quality but old microscope stage illuminators that used a huge rheostat in the 120 volt primary of a 12 volt transformer to supply a12 volt halogen lamp. The rheostat never failed but the mechanical belt/wheel system that turned it always broke. I replaced the rheostat and all the bizarre mechanics with a simple compact lamp dimmer, and some minor mechanical adaptations. On occasion the transformer would buzz, because of the non-sine wave input, but tightening the lamination stopped the noise. Often overlooked is that transformers can generally be reversed, to step up, or down the voltage.

Since a transformer provides isolation, here’s a trick. For line voltage isolation, use two identical transformers, let’s say 120 / 24 volt. Power the first one normally, 120 volts on the primary. Connect the second one backwards, by connecting the two 24 volt windings together. and the output is from the second transformer! so it’s step down 120VAC in/24 VAC out....then step up 24 VAC /120VAC. It really provides excellent isolation since both transformers are isolated. Be mindful of the transformer’s current capacity and don’t overload the arrangement. Other arrangements of transformers can give buck or boost voltages...raid the scrap box!

Len Powell

Finksburg, MD

My interpretation of your request is that you don’t want an AC power supply as large as most of the Variacs listed as 500 VA to 3000 VA on eBay. However, there exists a Variac as small as 300VA.

Better yet search for Powerstat 10B which is rated at about 200VA. This smaller unit puts out 0-130 VAC with 120 VAC in at about 2 Amps. This is a bare unit which needs to be mounted in an enclosure. Don’t like the greater than 30 V output? Then wire a 120:36 V step down transformer to the output. I have used this technique to drive a foam cutting wire.

Dennis Crunkilton

Abilene, TX

I’m looking for a simple circuit for a 24 hour electronic candle that uses very little power. The candle would drive a single LED. It would run for x hours (say five), then turn off; 24 hours after it has first activated, it would automatically turn back on for the predefined time.

I've found several ideas, but most of them surrounded the 555 chip which has a very limited time frame.

#03205

Scott Lapp

Simi Valley, CA

Please log in to post an answer.

Answers

It would be almost trivial to write a small program for a microcontroller to do this. I actually built almost the same thing to turn on a window fan in the evening and off in the morning. An 8 pin PIC with a 32. 768 Khz crystal. A single button reset the processor, which then would time for 24 hours, then activate the fan. Easy enough to add additional times. No display or time setting needed.

Richard Cox

Thousand Oaks, CA

I built a similar circuit to control a window fan. I wanted it to turn on and off at a certain time each day. I used an 8 pin PIC clocked by a 32.768 KHz crystal. The circuit was installed in the fan's remote controller.

Timer 1 was clocked such that it created a rollover interrupt every second. The software then counted the seconds and incremented a minutes and hour counter. Pressing a button connected to the reset pin set all the counters to zero. Then when the seconds, minutes and hours counters were zero every 24 hours it output a signal to the remote control button to turn the fan on or off.

What you want would turn the candle on when the hours and minutes are zero, then turn it off when the hours are five and the minutes are zero. Contact me at [email protected] for details.

Richard Cox

Thousand Oaks, CA

Does anyone still make oneoff circuit boards at home? What methods are being used by hobbyists and where do you get supplies?

#03204

Alvaro Collazo

Gulfport, MS

Please log in to post an answer.

Answers

For prototypes I use Press-n-Peel. You laser print the pattern to the PNP then use a clothes iron, or better, a laminating machine to bond it to the copper side of the board. Peel the PNP off the board and etch it. Clean the residue off the board then drill as needed and assemble it.

This from my post on forum.nutsvoltscom Re: Making PCBs at Home Post by Lenp » Wed Sep 02, 2020 3:43 pm

- Photocopy, or laser print the artwork onto overhead projector film unless you already have reverse artwork.

- If you use the the projector film, turn it over as needed to get a reverse image on the blue Press N Peel transfer film.

- You may have to tweak the copier’s toner for a dark image, and it might be a just a bit off scale, if that matters much.

- The circuit board should be bigger than the PCB pattern to help fix any misalignment problems.

- Clean the circuit board with something like a Scotch Brite pad, and wash well with alcohol to get rid of any oils or finger prints.

- Hold the board by it’s edges and align the PNP pattern on the board properly, taping one edge to keep it in place

- If you have a pouch laminator, run the board and film, with the taped edge leading,through using a pouch carrier.

- Without a laminator, you can iron it on with a clothes iron. Put a few sheets of paper on top of the film to keep it from slipping.

- The toner on the film will get sticky when hot, and bond to the board. Allow the board to cool, or rinse in cold water.

- If the board is missing a bit of a trace, choose to do it over, or repair the damage with a Sharpie marker.

- Acetone will remove the pcb pattern from the board so it can be reused if necessary, but clean it again.

- Etch in any available etchant. (I prefer amonium persulfate since it is less mess.)

- After etching, I leave the PNP pattern on until the drilling is done, then clean it with acetone but you can clean it first if desired

Overhead film is available online and maybe the big box office stores still carry it (who uses overhead projection any more?). PNP Blue film comes with an instruction sheet and it is available online, and from several electronic suppliers that also supply the copper board and etchants. Look online, it’s there as well as several videos showing the process.

This PNP process is great for a not too complex board prototype, but not for quantities. You can have a board from artwork to drill in an hour, correct your mistakes and go again without waiting for a board house turnaround and cost.

Good luck!

Len Powell

Finksburg, MD

I quit doing that when I spilled a gallon bottle of Ferric Chloride in the garage. A friend of mine was recently making some, but the materials are getting hard to get. Besides, ordering small quantities from China is way cheaper than buying the board and chemicals.

Richard Cox

Thousand Oaks, CA

The two most common methods I'm aware of are toner transfer and Photosensitive Dry Film. Most people seem to have much better luck with one or the other. I was never able to get toner transfer to work so I use UV film. The supplies for either are available at the usual sources (Mouser, Digikey, Jameco, Amazon, etc). There are a number of articles and videos on the web which describe the process better than I can.

Basically, a UV sensitive film is applied to the PCB, then a transparency is laser printed to overlay it. The areas blocked by the design are those which will be etched away (the print is a negative). The board is dipped in a developer for a couple minutes before it's washed with water. There are a number of echants, but the most common in hobby use is probably ferric chloride. If you use it, please check handling and disposal methods.

You may want to look at PCB prototyping services. Several advertise in Nuts & Volts. For $25-30 you can get 5 boards, 6 mil spacing, drilled, vias, masked, and screened, at your door in a week or so. Honestly, this is probably the way to go, unless you need faster turnaround. Or just wanna (a valid reason in itself!). It is very important to closely check the design rules.

Another possible option is CAD/CAM milling. However, I'm not aware of affordable equipment which has enough precision. I haven't looked in a while, so this may have changed.

Jay C

Louisiana

In the past, I designed and produced many circuit boards using several methods. By far, the best way to produce circuit boards is to just send the files to a company on the web and have them make them because if your time is worth anything, it is cheaper. However, if you insist on doing it yourself, you can etch them or mill out the unwanted copper, leaving the circuits that you want.

Milling works much better because circuit design software can produce files which can be converted to a program that runs on an othermill home router. It’s likely that other home routers can also be used, but the two people that I’ve seen do it used othermills. These machines are very popular at Makerspaces and school shop classes, etc. Adafruit uses this method to produce all of their one of a kind circuit boards for production testing their products.

This process starts with getting and learning KiCad software, which is free. YouTube has many videos on learning KiCad and Lady Ada often shows how she designs products for Adafruit using KiCad on her “Desk of Lady Ada” YouTube series. Watching this series from the beginning is suggested for anyone learning electronics.

After the KiCad design is done, it’s a matter of contacting the owner of a usable milling machine or sending the files to a board maker. The Hackaday guide: Why Etch A PCB when You Can Mill is suggested reading.

If you are dead set on etching your own boards, you can get several kinds of etchant from Amazon as well as some blank boards. However, a search of the web will likely show several other sources.

Forget any Ferric Chloride based etchant as it’s nasty stuff and works much slower than the better product Ammonium Persulfate, which stays clear enough to see how the process is coming along. You’ll also need a way to time the exposure of the boards and the right kind of lamp. I would suggest making the final board pattern on clear film that can then be taped over the copper clad board and exposed.

The other way to do it is to draw the pattern directly onto the circuit board with a “resist pen,” but it’s very hard to do an accurate job that way.

The transparent film can be printed on certain printers if the correct film stock is used, however getting the size of the image correct to produce the correct size printout might be tricky. We always drew everything 4 times bigger on graph paper and then had a photo shop reduce it 4:1 and print it on clear film.

Good Luck

Dale Freye

Grand Haven, MI

With the rise of the cheap board manufactures that can provide you a professional board for just a few dollars, this is something of a lost art. I still make my own boards most of the time. The time I have to bring my ideas to life is pretty limited and when I have a good idea I want execute on it right away.

When it comes to making my boards, I would call myself a jack of all trades and master of none. I use a few different methods depending on the complexity of the board and how polished I want the final product to be.

My go to method is photoresistive film and that produces the best output for me. Autodesk Eagle is my tool of choice for laying out my board, printing that output on laser printer transparencies and using a cheap laminator from the local big box store, a cheap light box and photoresistive film from eBay and I can lay down my artwork in about 30 minutes. There are plenty of Internet resources on how to do this online and it works great.

Etching is where the real issues are with making your own boards. It’s messy and dangerous. after all you are dealing with chemicals strong enough to erode metals. I used ferric chloride for years, and it gets the job done, but it’s slow and extremely messy. If you ever spill any, plan on the brown stain left behind to be there forever.

For the past 5 years or so I’ve been using muriatic acid (Hydrochloric Acid) and peroxide for etching my boards in a 50/50 mix. It is super effective and I can run to the local hardware store to grab a gallon, but it is has quite a few real hazards.

First and foremost it gives off chlorine gas so is has to be done outside and away from others and you must always use eye and breathing protection.

Secondly, anything within reach of the fumes made of ferrous metal will rust almost instantly. Both ferric chloride and muriatic acid like to be warm and agitated to work best. I made a simple servo driven device controlled by an arduino to rock the container back and forth and that speeds up the process greatly.

Drilling is next in line and again I have a few methods I use. My primary is just a simple micro drill press and hours of doing my best to hit the center of the pads. Drilling after etching allows you to use the raised copper pad to guide the drill bit.

Lately I have been working on a good technique for using my cheap 3018 CNC router to do this more effortlessly. By etching some alignment marks on two corners of the board I can pin the board down to the waste board on the CNC and let it do all the hard work. So far it is hit and miss but when it works it does a great job.

inally there is making it look good with some solder mask. While it is mostly for aesthetics for me, it does have a real purpose to keep your copper traces from oxidizing. I nearly always use Dynamask film.

Since I usually do photoresist film on my boards, and Dynamask works just like it, I have the tools out and on the bench anyway. Occasionally I use the liquid mask that you can order on Amazon or eBay, and it works, but it just doesn’t product the quality I get out of Dynamask.

So there it is, when you add all the time up and include cleanup afterwords, for a simple board you have used up the better part of a day. Is it worth it? No it’s not, considering the low cost of ordering professional quality boards now.

Will I keep doing it? Absolutely. While it is a ton of work and mess there is just something about it I really enjoy.

After I do my prototype on my hand made board and work out the details, I will get the real deal from a PCB service but the ability to test out an idea on a board the same day the idea hits you is awesome.

David Carter

Frankfort, KY

How do I calculate the number of turns for both the primary and the secondary windings of a transformer?

#03203

Opeyemi

Ibadan, Oyo

Please log in to post an answer.

Answers

The main problem with transformer design is the determination of the minimum number of turns for the primary. With too few turns, the transformer will overheat. Too many turns is only a problem if the turns will not fit within the “E-I” core windows.

We also need to determine what size of wire to use in the windings. With the aid of information extracted from Reference 1, we can design a power transformer having a 50 degree C temperature rise above ambient.

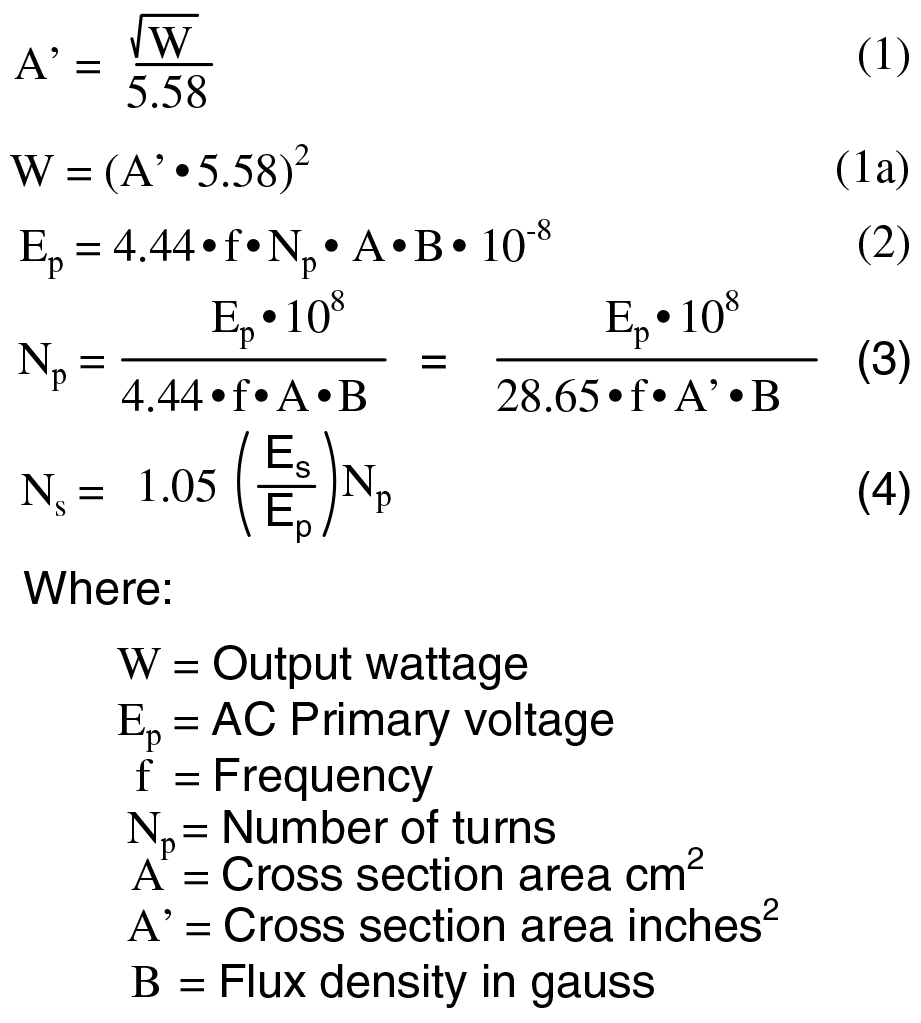

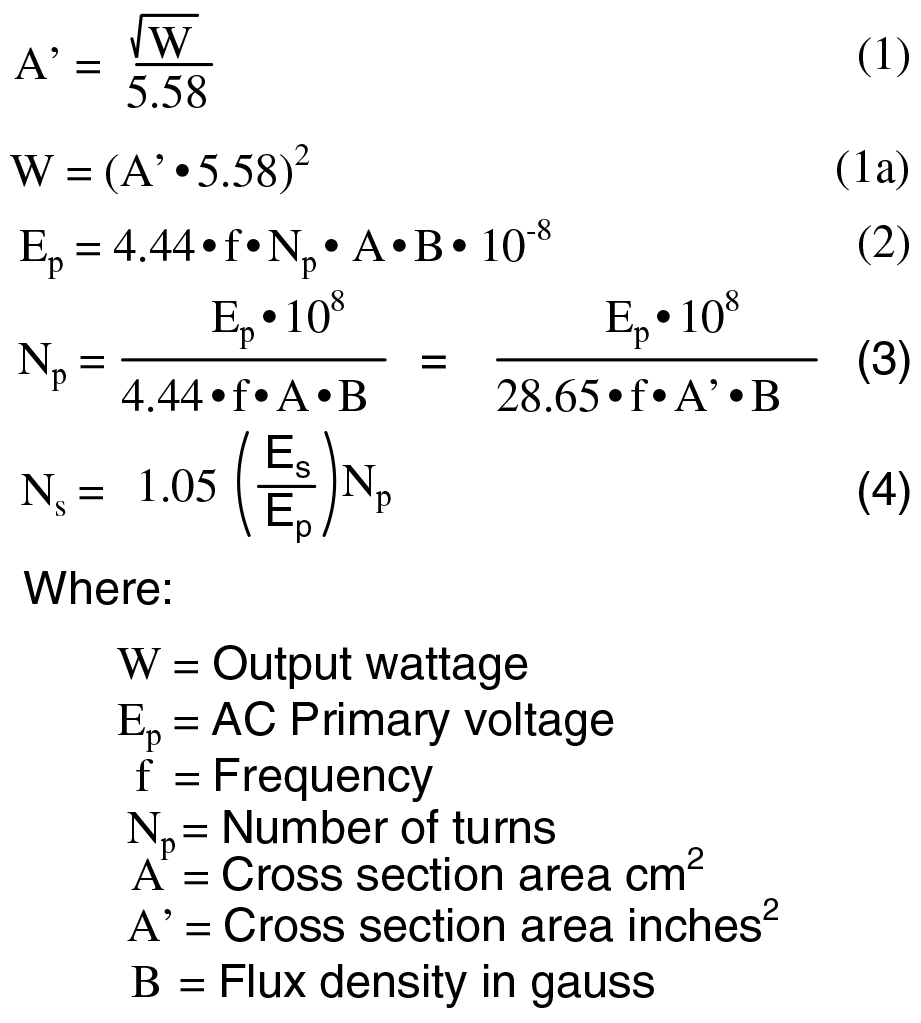

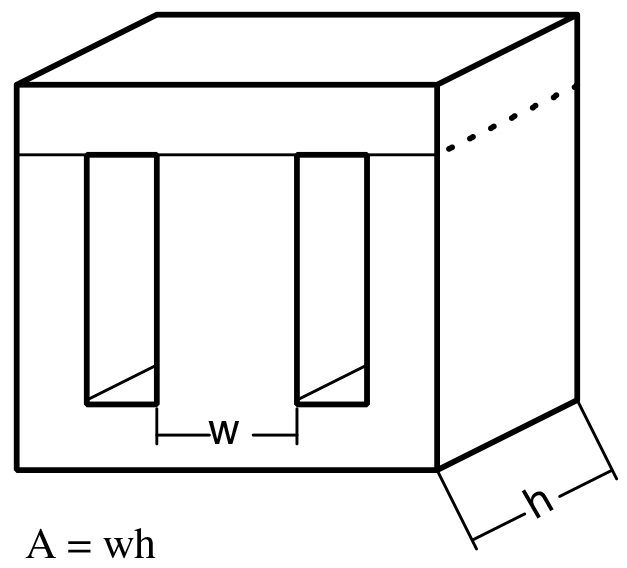

Figure 1

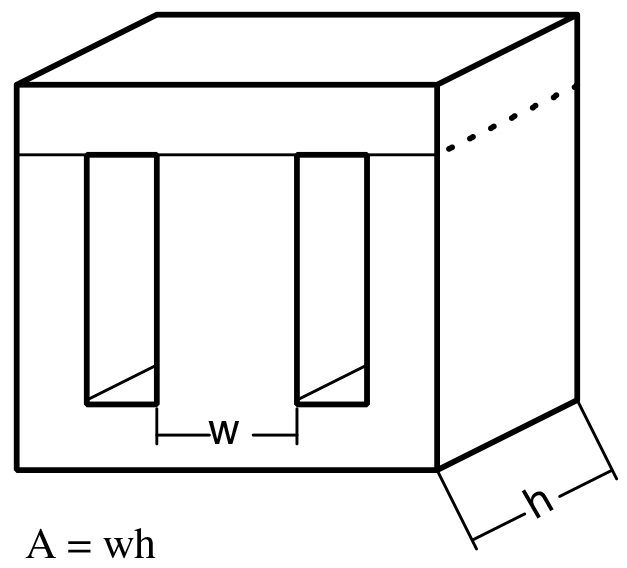

Use Equation 1 Figure 1 to estimate the size of the silicon steel laminated core required, given the wattage of your application. For example, a 12V 2.6A = 31.2W transformer requires a core with a cross section of one square inch (sqrt (31.2))/5.58 = 1.0. If you already have a core, multiply the height and width of the center leg to compute the cross section area as in Figure 2. Use Equation 1a to calculate the wattage rating of your core. The area will be A’ in Equation 3 if you measure in inches; A if measured in cm.

Figure 2

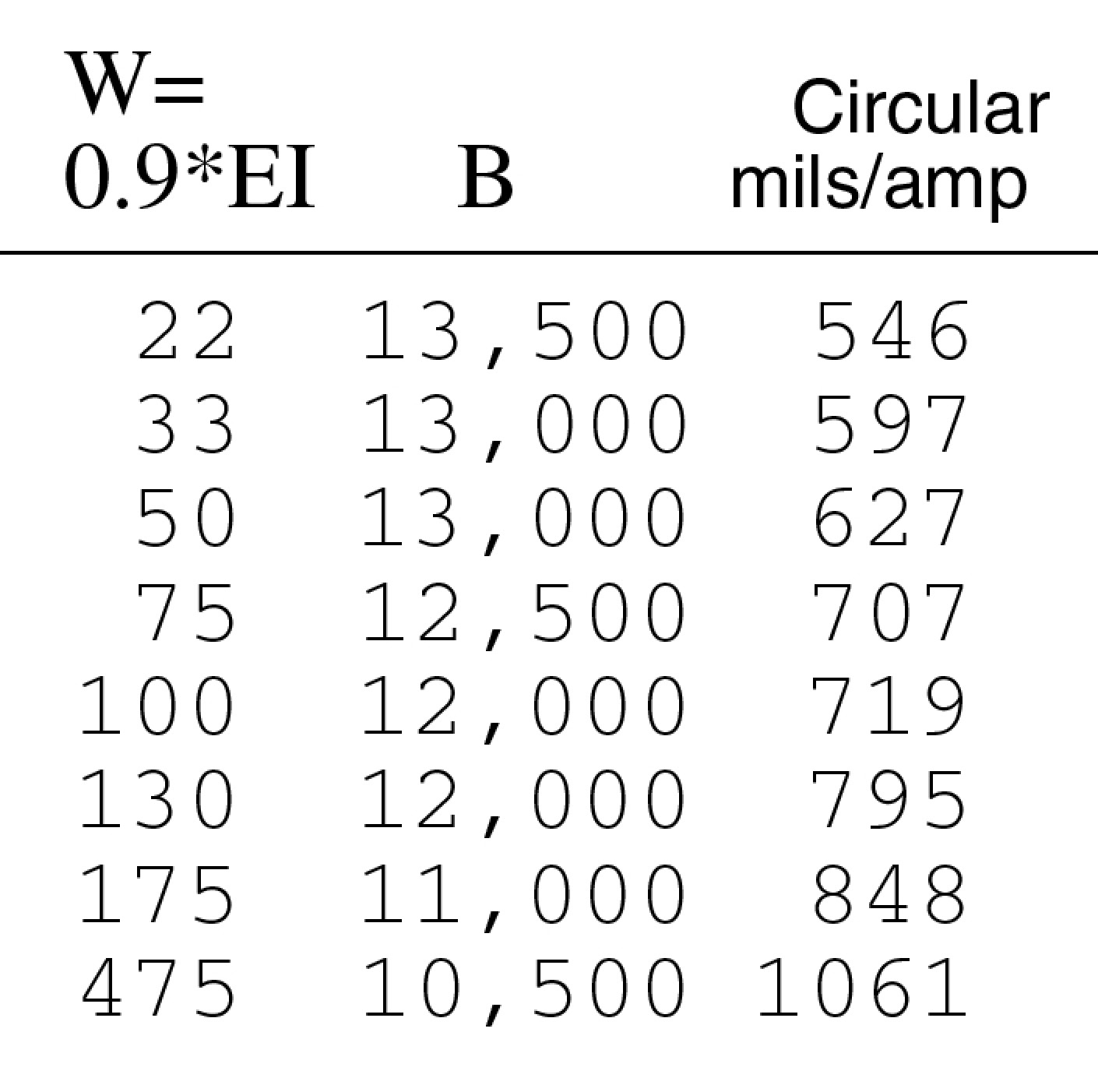

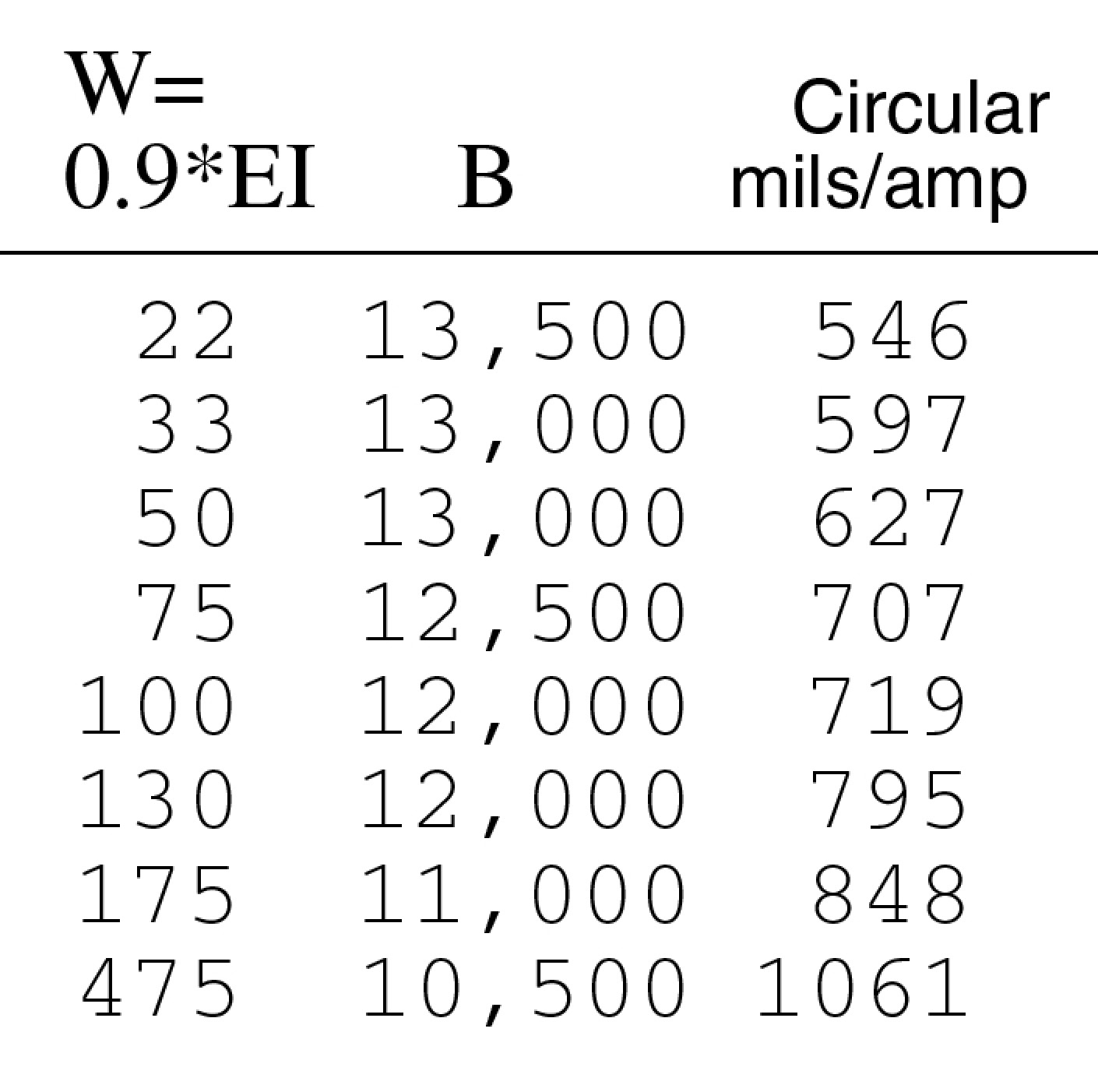

Equation 2 from Reference 1 was solved for Number of turns Np as Equation 3 The right-hand side of Equation 3 has a conversion factor applied to accept A’ in square inches instead of A in square centimeters. For our example as a 120 VAC 60 Hz transformer, set Ep=120, F=60, and A’=1.0. Consult Figure 3 for the recommended flux density B in gauss for the wattage of 31. Set B = 13,000. Equation 3: Np = 120(10e8) / (28.65)(60)(1.0)(13,000) = 537 turns.

Figure 3

Note that Equation 4 for Ns number of secondary turns has a 1.05 multiplier to account for winding resistance loss.

Continuing with our example, Ns = (1.05)(12/120)(537) = 56 turns.

The next problem is to determine what size wire to use for the primary and secondary windings. The size of wire depends on the wattage of the transformer. Small low-watt transformers dissipate heat more readily; thus, can get by with smaller wire size. Our 12V 2.6A = 31.2W example requires 597 circular mils of wire area per amp of current according to Figure 3. We need 597 * 2.6 = 1552 circular mils for the secondary wire. Looking up Reference 2, we find that 18 AWG wire has 1,624 circular mils of area; thus, 18 AWG for the primary. Since our primary/secondary turns ratio is 10/1, the primary current will be one tenth the secondary current (1/10)*2.6A = 0.26A. As with the secondary, we need 597 circular mils per amp. We need 597 * 0.26 = 155 circular mils for the primary. Consulting Reference 2, we find that AWG 28 has 160 circular mils for our primary winding.

Though I have not encountered any difficulty fitting the windings within the window space, you can estimate how much space will be required by consulting Reference 3 for turns per inch of a layer, and Reference 2 for wire diameter to estimate layer height. Use 90% of the turns per inch, 110% of wire diameter for layer height. Allow for thickness of the form on which the windings reside, allow for ends of the form, and insulation between the primary and secondary. Small diameter wire may require thin paper between each layer.

A complete re-wind of a transformer is only applicable to “E-I” cores that can be disassembled. Welded or epoxied cores cannot be disassembled. However, a few turns of a high-current secondary wire may be threaded through the window. According to YouTube videos, the secondary of a microwave oven transformer may be hacksawed and replaced with a few turns of heavy gauge wire.

Rather than a complete re-wind, consider re-using an existing primary by applying a custom secondary. Count the turns unwound from a known voltage secondary. Calculate turns per volt to aid in determination of the custom secondary turns.

- Reference Data for Radio Engineers, 4th Ed,1956, ITT, pp 275.

- Copper wire gauge table, www.ibiblio.org/kuphaldt/electricCircuits/Ref/REF_3.html#cuwire.tbl.

- AWG gauge vs. turns per inch, www.ibiblio.org/kuphaldt/electricCircuits/Ref/11099.png.

Dennis Crunkilton

Abilene, TX

My son has recently become a model train enthusiast and asked me how to control multiple trains on the same track. Is it possible and how would one go about building a controller?

#03202

Paul Sills

Grand Rapids, MI

Please log in to post an answer.

Answers

To do what you want you will need to use the system called DCC. To see an explanation of how it works, see Practical Electronics, Jan 2021 where they show (on page28) how the voltage going to the tracks is encoded with digital control information as well as being the power source for all the trains and other equipment controlled by the system.

I suggest reading the magazine at a book sellers place while enjoying a drink because the magazine costs $12. I would not suggest building the circuit when similar factory built units are available, because the blank circuit board is 12 Pounds each plus VAT and shipping from GB.

Amazon lists a DCC controller called NCE PROCAB #5240010 which looks like a large TV remote with a display that can control your whole layout. This equipment is not cheap.

A review of the Bachmann HO scale "ChargerSC-44" diesel locomotive with AmTrack Cascades 1400 paint as shown in Model Railroad News, May 2021 is pretty favorable. It is part #67904 MSRP $469 from Bachmann Trains. 800 356 3910 https://bachmanntrains.com Also check out Walthers 800 487 2467 https://www.walthers.com for some less expensive models.

I hope this will be useful and get you started in the right direction.

Dale Freye

via internet

You and your son are in luck, controlling multiple trains on the same track is a problem already solved with Digital Command Control (DCC). The beauty of using DCC is that the National Model Railroad Association (NMRA) has a series of electrical standards that define the signal between the transmitter (known as the command station) and the receiver (known as the decoder). The NMRA published the first of the DCC standards (see https://www.nmra.org/index-nmra-standards-and-recommended-practice) 20 years ago, so these standards are well established and stable.

There are multiple manufactures of DCC systems. Each system has a command station to create the signal and a booster to amplify the signal that is sent out over the rails. The manufacturers differ in the manner they input the user signal into the command station, via a throttle (also called a cab), since this in not covered by the NMRA standard.

A decoder is placed in each locomotive. There are also multiple manufactures of decoders. Compliance with the NMRA standard allows any manufacturer’s decoder to correctly interpret any manufacturer’s DCC signal. Should you wish to purchase a “starter set”, my advice is to avoid over-researching, since given the time-honored DCC standards, there are no “bad” systems on the market. Rather, find a neighbor, friend, or local model railroad group that is willing to assist, then purchase whatever DCC system they are using.

Being a Nuts and Volts reader, you have other options to explore. Type “DYI DCC” your browser’s search. You will find numerous variations using an Arduino or Raspberry Pi to provide the signal while an old computer running a Java-based cross-platform program, JMRI (see https://www.jmri.org), provides all interface. If your son’s locomotives do not have a manufacture installed decoder, he will be able to learn advanced soldering skills.

In summary – Jump into Digital Command Control and get much more out of the hobby than you and your son originally expected.

Dick Schwanke

Model Train Controller

There is a model train system called DCC where electronics in the train engine are controlled by a wireless remote control. Multiple trains can be controlled for speed, lights, horns, smoke etc. Visit a good hobby shop that has a train section or search online.

Richard Cox

Thousand Oaks, CA

What you're probably looking for is DCC (Digital Command Control) technology. I use the Digitrax system for my layout. There are also a few DIY projects out there: https://dccwiki.com/DCC_Projects.

The simplest explanation for this is each loco has a unique decoder embedded inside. The tracks are always energized and commands are sent along the tracks from the controller, causing the recipient loco to execute that command. Good luck!

Michael Picco

Placerville, CA

I have a rather complicated TV reception system. I have four antennas all successfully combined into one by using modules to convert the RF signal to VHF siganls. What I am lacking is a constant input for all signals into the combiner.

I would like to take signals from 54-216 MHz with 1-8 dBmV input and put out 18-25 dBmV with as little noise as possible. It would be great if I could clamp all signals to 25 dBmV.

#03201

Howard Epstein

Gilford, NH

Please log in to post an answer.

Answers

The Televes Avant X would be an ideal solution for that situation. The Avant X is pretty much an MATV headend in-a-box. It is a filter > processor > amplifier allowing to individually filter RF multiplexes coming from up to four different antennas, automatically adjusts the levels individually for a balanced response, and even allows to frequency-shift when needed if two same RF frequencies are coming in from two different markets.

On top of that it doubles as a launch amplifier with a programmable output level between 30 and 55dBmV.

Javier Ruano

Denver, CO

I haven’t done much with PICs recently and I used to use a PICKit1, which is now obsolete.

Now, I want to re-program something I made about 10 years ago, my PICKit1 is no longer usable, and my old development software won’t play nice with Windows10.

I look at the array of products available and I am overwhelmed. So, what do I need to have a modern equivalent of a PICKit1 and what software do I need to program PICs using C?

Also, in addition to a Windows set-up, is there a Linux-compatible option as well? I tried contacting MicroChip but got no help there.

#

Keith Ujvary

Oliver, British Columbia

Please log in to post an answer.

Answers

Consider the Picaxe from Revolution Education, low cost, easy interface and free programmer with simulator, (works with Win10) and they have a very active forum. OK, so it's a PicBasic language version, but...it gets many jobs done quickly, with low cost and overhead. There's a wide range of PicAxe chips with tons of I/O. ADC and much more, driven by the power of PIC Microprocessors. (No financial connection, just a satisfied user!)

Len Powell

Finksburg, MD

I would suggest using a PICKIT 4, part number PG164140 for hobby programming. I would suggest moving to MPLABx for the development environment and the MPLAB XC compiler for a C compiler. Most can get away with the free version. The tools also work with a MAC or Linux. I do suggest using the native version and not running under emulation so the directory structure can be the default. Software is all available on the Microchip web site and the programmer/debugger can be bought direct or from many different distribution options.

You will probably need to make some code changes to align with the changes made over the years to the software but it should not be too much effort. If you are doing more severe development you may want to consider the ICD4 but the cost is higher and may not be needed or justified depending on your use.

Larry G Nelson Sr

Webster, MA

I use picprog under linux which you can find in the repository to program PIC chips using a home built usppicprog programmer. You can either install it through the GUI software manager or via the command line by running "sudo apt install picprog" in terminal.

Derek Tombrello

Shelby, AL

I was wondering what would be suggested to properly provide protection of a device with a 5V low power regulator and LED driver against automotive transients, and reverse voltage that is connected to an automotive starting battery.

I presume a TVS diode could be used, but should it be bi-directional or uni-directional? A Schottky diode could be used for low voltage drop, first in line for reverse voltage protection, but it would have to withstand the clamping current of the TVS diode.

Would it be be necessary to include a resettable fuse if the transient lasted too long and exceeds the power rating of the TVS diode?

#02202

Wayne Carpenter

Omak, WA

Please log in to post an answer.

Answers

Using a uni-directional TVS diode and series Schottky diode is an excellent start. This will take care of garden variety transients caused by relay switched inductive loads. Cars are full of those. Some capacitors on the input will help too. In addition, there are a couple of unique automotive transients that require attention.

The first is called double battery jump start and happens when the tow truck guy jump starts your car and has a second battery in series with his truck battery hooked to his jumper cables. This results in about 26 volts and a typical automotive device must withstand this for one minute.

The second transient is called load dump and occurs when the battery becomes disconnected while being charged. The alternator regulator cannot react instantly and will generate a transient that can reach 60 volts peak and then slowly return to normal charge voltage over about 400mS.

I solved these problems by using regulators that would stand the 26 volt jump start. You will need a bit more heat sink but it only lasts one minute. There are some automotive regulators that will stand the 60 volt load dump as well. An example is the LM2931. However, it is low current (100mA).

Another way to deal with load dump is use a resettable fuse (PPTC) in series with the input diode and use a large enough TVS to blow the fuse. In case you have not dealt with automotive 12 volt systems before, the normal run voltage is actually 9-16 volts with nominal about 14 volts.

Jim McGrew

Saline, MI

For more accurate timekeeping, how would I connect a GPS time receiver module to the PIC16F876A of the Numitron clock that is featured in Nuts & Volts?

#02201

BrunoZ

Elmira, NY

Please log in to post an answer.

I need help to improve my neat SALT WATER Voltaic cell. I started with copper as my positive elactrode and aluminum as the negative electrode. The result is 337.5 millivolts. Then, I temporarily used a steel plate and I got 830.0 millivolts. That was better, but its an alloy and not pure iron. So, is there a better metal that can beat both of them? I need to get to 1 volt or better. So what metal will do that in salt water?

#01203

Victor Davis

Horton, AL

Please log in to post an answer.

Answers

Mr. Davis seeks information to construct a voltaic (“galvanic”) cell whose potential would equal or exceed one volt using a salt-water electrolyte. I found a short treatise on that subject at https://cathwell.com/galvanic-series/. A zinc-titanium electrode pair would produce just slightly in excess of one volt in salt water. Other combinations are listed in the referenced article.

Peter A. Goodwin

Rockport, MA