ISSUE: August 2016

I want to extend my home alarm system to my garden shed. The shed has power but no simple way to get wire to it from the house. Is there a DIY wireless method to try?

#8165

Woodrow Young

Lima, OH

Please log in to post an answer.

Answers

Visit the "Alarms and Security" department of your local Home depot (or similar) and look for a "basic" wireless system with magnetic door/window transmitter sensors and a matching wireless receiver. Install the sensor(s) in your shed, set the transmitting "address" code(s), and install the batteries. Next, install the receiver near your existing Home Security system and run wires (i.e., #20 or #22 twin-lead) from the wireless receiver's "Trigger Out" (or similar "alarm contact" relay) connection to your main system's "External Trigger" (or similar) input and connect the receiver to power. NOTE: some wireless alarm receivers DO NOT have the "Trigger Out" capability - try to get one that does. Ensure the receiver has battery backup power if the main AC power is lost!

Next, test the shed system: put your main system in "test" mode. Trip one of the shed sensors and verify the wireless receiver activates the "Trigger Out" contact, which should trigger your main alarm via the "External Trigger" input (unless the receiver DOES NOT have the "Trigger Out" capability). Reset the system and repeat for the other shed sensors, verifying each tripped sensor activates the alarm (main system via "Trigger Out" or the wireless receiver alone). When you're satisfied all is working, take your main system out of "test" mode so the shed will be monitored.

NOTE: make sure you DISABLE the shed system before purposefully going to the shed or you'll get a false alarm! Also, ensure you RE-ENABLE the shed system when it's otherwise unoccupied.

Ken Simmons

Auburn, WA

Look at wireless remote doorbells, such as you can find at local hardware stores. They can be really cheap. Just re-work the doorbell button to the shed door sensor and then tap off the receiver (may require a bit of interface electonics, such as an optoisolator) in the house and feed to your alarm system.

Pete Lunt

Cary, NC

I have used the Wicked Devices 433Mhz system with Arduino controller when it is inconvenient to run a cable. The effective range is up to a couple of hundred feet. This unit has 4 channels that can be used and a lot of documentation & code is available on the internet.

The unit is also called Nanode Transmitter & Receiver . See www.wickeddevices.com for more information.

Gene Sellier

Fairhope, AL

There are a couple ways you can go with this:

1. Contact your alarm company and find out if the security panel in your home directly supports wireless devices. Most modern ones do. They would install a wireless door contact in the shed and program it to the alarm panel. Some security systems already have wireless built in or they may need to add a wireless receiver.As a bonus, you could add on a wireless keyfob to arm/disarm your house from the driveway. This would cost more than a DIY solution but they should be able to match up the proper equipment to make the setup as reliable as possible.

2. For a more DIY approach, Linear has available a wireless transmitter & receiver that could be integrated into any security system regardless of age. “Linear D-24A” is the transmitter and “Linear D-67” is the receiver.

The transmitter uses a battery and would still need to be connected to a set of door contacts on the shed door. The receiver wires directly to your security panel to power and one zone. You would want to use a spare zone on the security panel, but keep in mind, the zone may still need to be programmed by your alarm company. And if your security panel dials out to a monitoring company, your alarm company will need to add that zone to your account so that activation of that zone would alert the proper authorities.

Eric D. Bailey

Cecilton, MD

A simple cheap and dirty solution would be to use one of those wireless door bell setup’s that most hardware stores sell.

Place simple door (normally open) switches in parallel with the “door bell” switch mounted in the garden shed. Use a low current reed relay across the speaker output of the reciever in the house. Connect the normally open reed contacts to one of your alarm panel loops.

Wala, a cheap and dirty solution. You may need to add a latching relay of some sort.

Ray

Vancouver, Canada

I would like to add a "rain detector" to my sprinkler system that would automatically disable the sprinklers. The system uses an old-style mechanical "dumb" timer. How about a simple circuit to do the job?

#8166

Gary Hunt

Southfield, MI

Please log in to post an answer.

Answers

You can buy a normally closed SPST switch containing a water absorbing material that expands when wet to open a microswitch. This is placed in between the common side of the valves and the return line. The switch can be adjusted to open after an appropriate amount of rain has fallen. They are sold by most sprinkler manufacturers in home improvement and hardware stores.

Horton Prather

Buford, GA

It has fallen to me to teach a short course on electronics for a summer camp program near our home. I would welcome suggestions for curriculum! The kids are ages 8-12.

#8167

Levi Coughlin

Dunmor, KY

Please log in to post an answer.

Answers

Summer is about over so this might be useful for next year but this is what I would teach kids if I had about a week to do it.

DC/AC:

- Batteries and LEDs

- Types of electricity:

- DC, AC line power

- Power Line Safety

- Tesla coil RF

Series and Parallel game:

- Lines on floor

- Switches

- Rules

- Leader

AC line safety:

- Overloads

- Wet areas

- Reducing power use with CFL and LED bulbs

Takeapart Day:

- VCRs

- DVD players

- Computers and hard drives

- Problems with TVs - High voltage breaking glass

- Dangers of Micowave ovens and how to avoid them with proper supervision

The series and parallel game is played on a gym floor or grass area with lines laid out with painters tape or yarn and 4" nails. Use small rugs for batteries and lamps. Have kids to man the switches which are yarn sections with weights on the free ends.

The teacher yells out "switch one close' etc. then the switches move and the kids stationed along the "wires" move like electrons if the circuit is complete. Do a short circuit too where the kids have to move quickly and the teacher breaks the circuit and yells stop/sit down. This comes last followed by a comment and question time. This is modeled after the on stage demos that are part of Harvard's famous CS 50 class.

Have a local fire official do the line voltage safety lesson because they do this all the time.

Be sure to have tiny torx drivers for taking the super magnets out of hard drives.

I would like to see some guidelines for the takeapart day like:

- Unplug all wires rather than cut them

- Watch out for anything that has ink in it or on it and wear gloves while removing that part to the trash can

- Recycle everything not saved for parts.

I hope that you find this useful.

Dale Freye

via email

Recently, I too was asked to make an electronics presentation for the age group you mentioned. The library staff person referred to me as a docent, or lay presenter. The areas I get excited about would seem not to transfer well with this age group, so I needed help. Thankfully I was well-advised by the youth librarian who assisted me in creating and talking about very basic electrical experiments that she hoped would conclude with a hands-on soldering demonstration.

The first experiment employed a basic compass with five or so hand wound turns of 30ga. magnet wire circling it, powered with one AA battery. So why does this make the needle spin? Discussion about magnetism and electrical relationships. Can anyone envision a motor in this? (hold just one or two seconds to keep wire heating reduced)

The next presentation offered the very simplest circuit with a 'schematic' drawing representing the actual physical setup of a power source, wire connections, and a (lamp) load. Then a switch is added and drawn. Some discussion then about how current behaves and flows in this circuit.

The third presentation involved a zero center galvanometer (+ - .001A) those large clear classroom kind work great, the terminals connected to the winding of a nail or screw type electromagnet with a small magnet fluxing a field to induct current then swinging the needle both directions toward a basic conception of Alternating Current. Good time to mention diode rectification in the ensuing discussion.

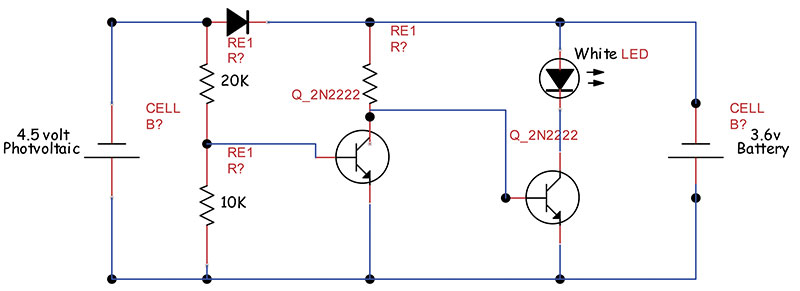

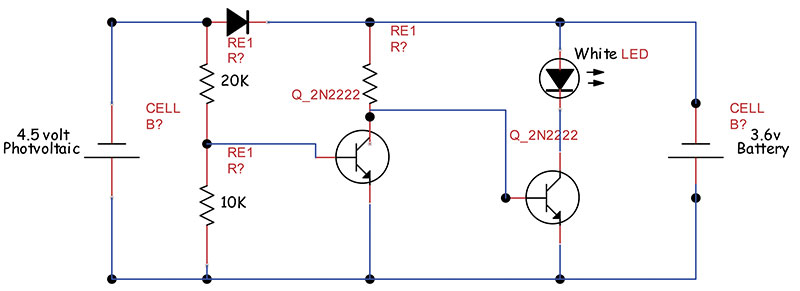

The last was a very well-received LED yard light demonstration. A small solar panel, with an electronic control circuit connected to that zero center meter showing current direction both powering a white LED and charging a battery configured like this:

Schematic of Yard light

Just to the right of the White LED junction, between the 3.6volt battery, insert the zero-center galvanometer. A 3-4 ohm shunt between the + - meter connections offered dramatic visual current direction. Raise or lower shunt resistance as needed.

The kids responded well using objects and their hands to shade the photovoltaic panel watching the meter swing and the white LED turn on and off, either charging or emitting light with only a simple transistor circuit. As they were marveling I offered a brief description of the transistor operation in a schematic drawing describing the details of on-off (Schmitt) switching.

We DID have time to solder at the end. With a circuit board clamp at a comfortable angle, I used a 15 watt Weller with the LED lights, put my glasses on describing the need for a clean, tinned, tip and began soldering a hole-through PCB describing the process as I soldered each tiny pad. Would you like to try this? They all did, and I get teary in how excited they were when they completed their section of the many other pads. At the end of our class, the youth librarian shook my arm off in thanks, but I easily enjoyed it as much. It will be easier than you think. Have fun.

Michael Greenlee

via email

Suggestion depending on length of camp:

- Build an LED flashlight.

- LED flashlight with dimmer.

- Crystal radio.

- Crystal radio with one-transistor amplifier.

Chip Veres

Miami, FL

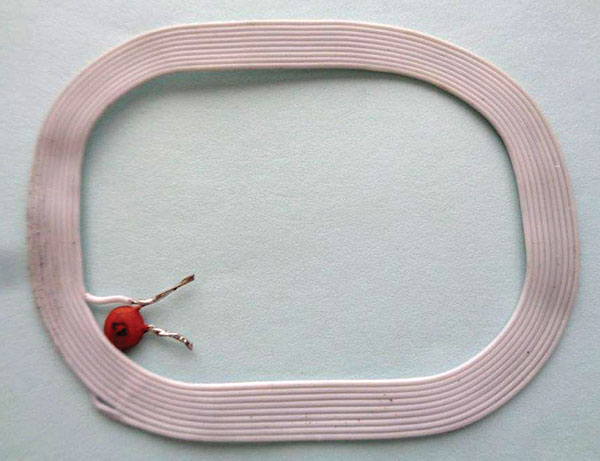

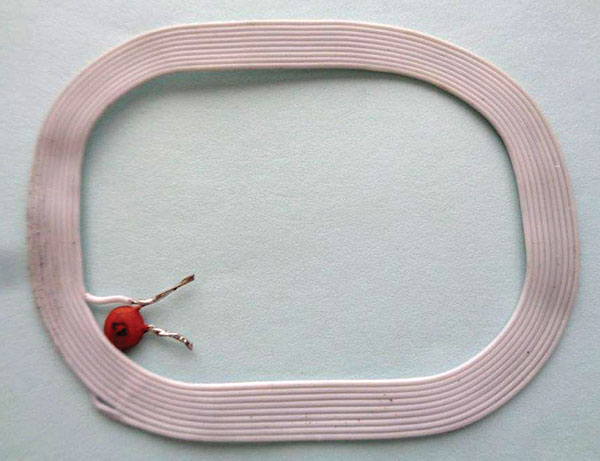

My old billfold was worn out over the years. I planned to retire it when I noticed in back was a coil of 10 revolutions (6 cm x 4.8 cm) with a capacitor marked 47 soldered to the ends, welded in plastic, the size of a credit card. I had never noticed this. Could it be a security feature to prevent devices from getting to my credit card? How would it function? Just curious. A picture of it is shown above.

#8161

Christian Bock

via email

Please log in to post an answer.

Answers

What you have is an LC parallel resonant circuit in which the inductor (L) is a loop antenna similar to the ones found in old AM radios, and 47 picofarad capacitor (C) tuned to resonate at the 13,56 MHz signal frequency used by credit card RFID chip readers. At this resonant frequency, the parallel LC circuit has a very high impedance and effectively absorbs most of the RF energy from a hackers reader to protect the information on your credit card chip. I bought a couple of wallets that protect RFID chips, which have a layer of aluminum foil sandwiched between the layers of leather and cloth in the wallet. It makes a Faraday cage which prevents the hackers RF reader from stealing my card info.

Tim Brown

via email

It looks like you have the remains of a security device that was intended to prevent shoplifting the wallet when it was new. Checkpoint Systems or something like it. Someone forgot to remove it when the wallet was sold?

Chip Veres

Miami, FL

The lights on my boat trailer work erratically. Sometimes they work fine (turn signals, brakes, and running lights); other times, when I press the brake pedal, only the right turn light comes on and all the running lights go out! Short of tearing it all out and re-wiring from scratch, any tips on how to locate the fault and fix it?

#8162

Craig Priolo

Saint Louis, MO

Please log in to post an answer.

Answers

Sounds like a grounding problem. Take a jumper cable between the hitch and trailer frame to make sure you have the trailer grounded. If this is a tilt trailer then also jump across the pivot point to make sure all sections of the frame is grounded. Lights work? Then check your ground to car frame on car side of trailer light plug. Check the ground on the trailer side of plug to trailer frame. If it tilts then install a permanent jumper across the pivot. The reason it is intermittent is the ground is only sometimes through the hitch ball. When there is a no ground situation, the lighted bulb is feeding back through the other bulbs positive wiring.

Steve Benson

New Castle, IN

There is not enough information given to arrive at a certain answer, since a lot of necessary information is missing but it looks as if you have a ground problem. On my trailers I have seen the same issues and the culprit was a poor ground connection, raising the ground potential at the offending lights so high, that the running lights turn off when the relatively large brake/turn lights are turned on, assuming the running lights are grounded at the left lights.

Diagnostics is easy, measure the ground potential directly at the offending light bulbs against a known good ground, the trailer connector is best. However, it needs to be said that there are many different wiring schemes such as 4-way, 5-way and 7-way plugs, electric brakes, break-away and other batteries and relays which can cause issues – if need be, you need to measure all signals and draw your own conclusions. To get a good ground, the connections need to be corrosion and oxidation free. You can use dielectric grease to prevent early corrosion.

I have had to run separate heavy ground wires to all consumers in star fashion starting from the plug to fix serious issues. Lights which get their ground connection through their mounting studs and electric brakes with their high current draw are especially troublesome.

Walter Heissenberger

Bennington, NH

I have spent my life fixing the sins of good intentioned people who were in a hurry. First of all, NO, there is no easy fix! But understand the harsh environment, and you can stave off the corrosion gremlins for a good while. Replacing old lights with the new waterproof LED fixtures makes huge sense.

(1) Assume that ALL parts are corroded, and NONE are salvageable. If you won't do this, REMOVE and REWIRE the ground bolt. Grind, file or sand the frame where the new bolt will attach, and GREASE EVERYTHING thoroughly. Use the cheapest tub of wheel bearing grease from the auto parts store, or (better) marine grease for $2 a pound more. Better to run separate ground wires to all lights individually.

(2) GREASE ALL WIRES BEFORE YOU PUT THEM INTO THE CRIMP TERMINALS. Do NOT solder anything that you can crimp. Fill the crimp terminals full of grease before you insert the wire, also. Don't worry, the crimper will expel enough grease to make a good connection. Pull on the finished crimp splice. If it comes apart, learn how to do it right. My all-time favorite crimper is the Dimple-Crimper. I know it is only for bare uninsulated barrels, but it holds the wire better. Feel free to fill a piece of shrink tubing with grease and put it over any splices.

(3) OPEN UP any old splice, as it was likely done poorly. Use a Western Union Splice (soldered) or a new butt-joint connector. TRUST NOTHING!

(4) Sand the bulbs clean, then grease them gently. The grease keeps the corrosion from starting. Clean the sockets, too. Better to replace them. ALL METAL PARTS ARE SUSPECT. Jumper over any rivet from brass piece to brass piece with a short piece of wire.

(5) Remember, I TOLD YOU SO! If this doesn't work, go back and put in all new wiring, but DO IT RIGHT. The fresh or salt water environment is out to get you, and to eat all your stuff. Live with the constant cleaning/greasing/replacing of your equipment, and keep after it! There is NO EXCUSE for losing a brake light!

Hap DeSimone

Santa Barbara, CA

What you describe are classic signs of a bad ground (return) line to your trailer. The quickest way to confirm this is to take a heavy jumper wire and connect it to a clean metal spot on the trailer and the other end to the towing vehicle bumper or frame. (using one line of a battery jumper cable works good for this!) If the lights work normally now, it means the trailer lights were being grounded only through the trailer hitch. Even on the smallest four pin trailer connector, one pin is for the ground connection. It is the white wire on the pin that is opposite of the other three. This is usually corroded and should be cleaned or replaced. I have seen some trailers that do not have this wire connected at all!. Make sure it is actually connected to the frame. Most auto or RV stores have replacement plugs and sockets. The standard four pin wire connector color code is: yellow is left turn, green is right turn, brown is tail lights, and white is ground.

Ron Kmecik

East Springfield, PA

Likely poor ground connections cause the intermittent lamp behavior you observe. A trailer frame provides a poor common ground for lamps. Run a separate ground wire to each lamp socket and join them near the vehicle-to-trailer connection. Then use a single ground wire from that point to the trailer-side connector's ground pin. Also ensure you have a good clean connector. Next, connect the vehicle-side ground wire to a good grounding point on the vehicle's frame. Better yet, run a separate vehicle-side ground back to the battery. Fourteen-gauge stranded wire should work well. Check connections regularly.

Jon Titus

Herriman, UT

No doubt about it, trailer lights are a pain. There are a multitude of possible trouble points.

First of all, if you are launching your boat correctly, then the back end and sometimes the whole thing gets dunked under water. The channels of the trailer frame get filled with water and never really have a chance to fully dry out. Since the channels are steel, they begin to rust. Rust turns clean, shiny ground connections into high-resistance points and strange things begin to happen. The drain holes allow little critters access to the inside of the channels where they set up housekeeping which includes munching on your wires.

The cable feeding the lights from your vehicle gets a lot of flexing and can fail in a whole bunch of ways, especially that flat 4-conductor stuff. The lampholders on the trailer are also prone to failure from the periodic dunkings, even the ones claiming to be sealed.

And do not forget the connectors themselves. The vehicle mounted connector is vulnerable to all kinds of weather conditions 365 days a year which means it is susceptible to oxidation and corrosion.

I have to warn you right now that you have to be careful when working on the vehicle connector, especially if it is the large, round 7 contact type. One of the contacts has full vehicle battery voltage on it continuously, protected by a 30- or 40-amp fuse. If you accidentally short this contact to ground, additional damage can result.

So disconnect the battery first, or at least pull the fuse. Diagnosis: first thing you have to do is isolate whether the problems are vehicle or trailer related. Could be both. The auto parts store will sell you a nifty little tester with several LED’s that you plug into the vehicle. and will indicate whether or not a voltage appears on a specific contact when the corresponding circuit is energized.

These can be useful, but have their limits. An LED is a low-current device compared to the current drawn by your lights. If you have a less-than-perfect connection somewhere in the system the LED will merrily light up indicating everything is wonderful. But substitute a real world load of a few amps and the resistance of the poor connection will drop the available voltage dramatically. Same goes for using your multimeter: the current drawn by the meter is way too low for high resistance connections to have much of an effect. What you can do, however, is connect the trailer to the vehicle, then start checking various points with the meter since the trailer is the real world load condition for the circuit.

Establish a good connection to the vehicle battery negative terminal (assuming a negative ground system) for the minus side of the meter. Then begin checking the various points on the trailer while the lights are energized.

You can also check for crummy ground connections by touching the meter probe to the shell of each lamp. You should read no more than a few millivolts from the shell to ground. Anything greater than a volt is definitely suspect.

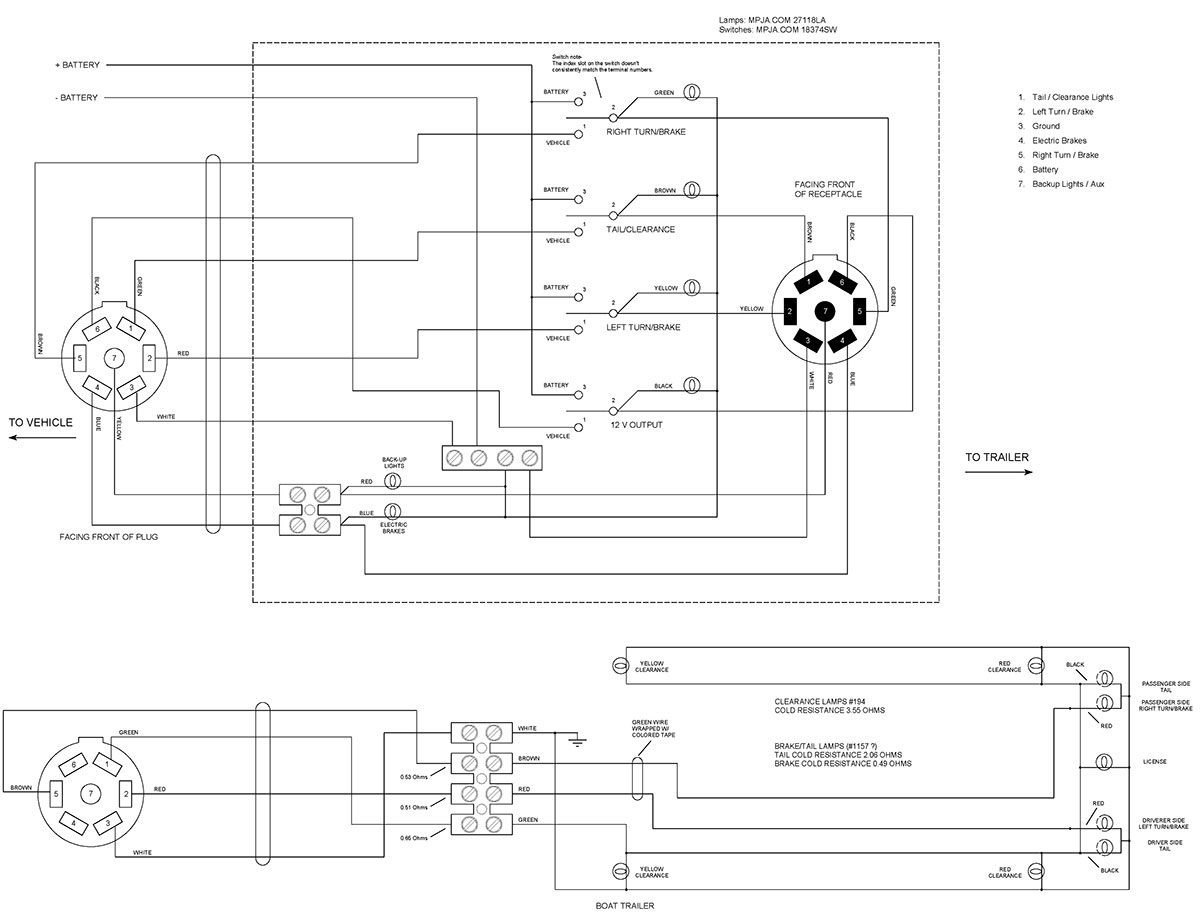

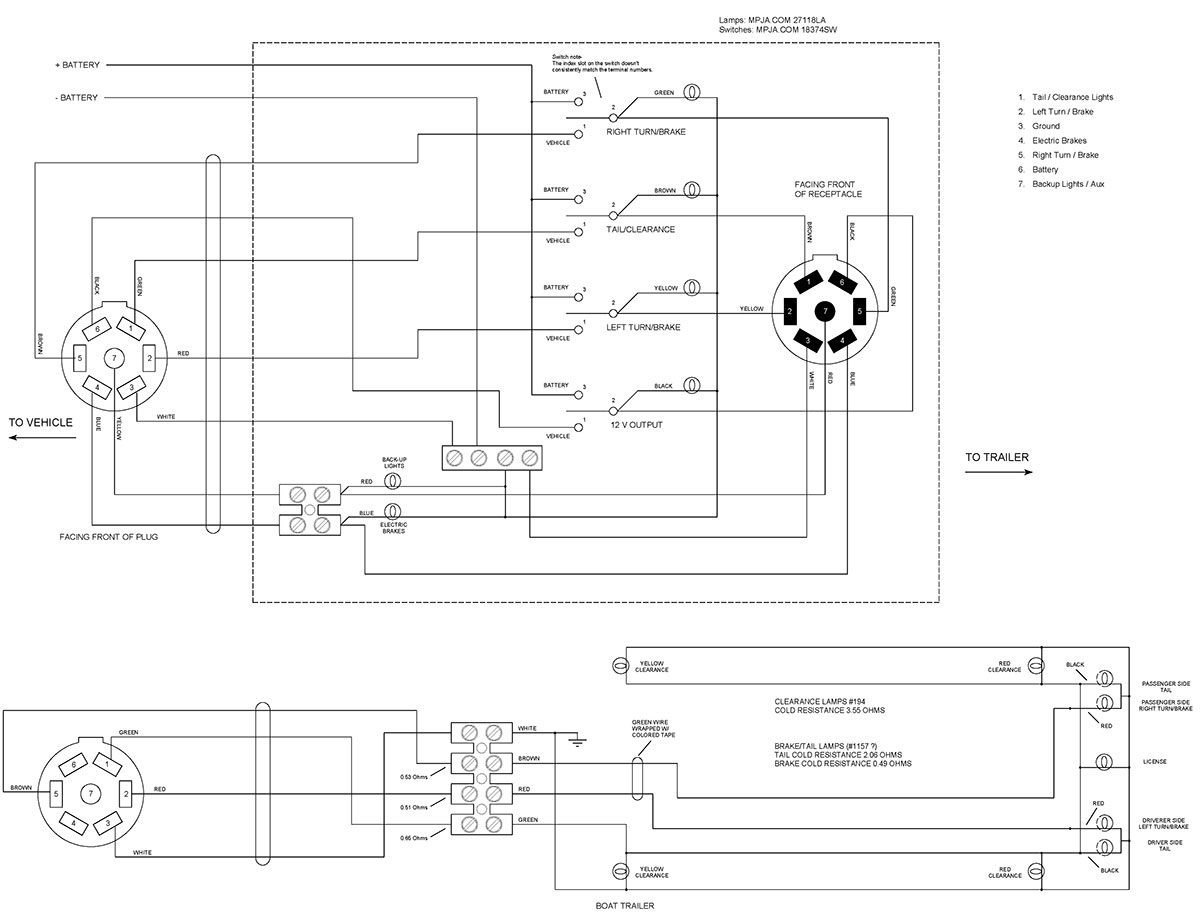

What I ended up doing is building a box that connects between the vehicle and the trailer, with a lamp (incandescent, for the reason cited above) for each circuit so I can see at a glance whether the circuits are getting power from the vehicle or not. The box also allows me to connect a stand-alone battery to the trailer and power each circuit individually for testing purposes. The diagram for it is below, should you be interested. It has saved me lots of time and trouble.

Jerry McCarty

Jackson, MI

Sounds like a classic case of a bad ground. Boat trailers are bad for this type of problem. Most manufacturers use the steel body of the trailer as the ground return to the tow vehicle.

You will need to check the ground connections at each lamp, and at the harness (to the tow vehicle) connection. When you find the bad connection, clean any rust or corrosion off, then use a paste corrosion inhibitor (zinc suspended in a heavy grease such as this: [url=http://sw-em.com/anti_corrosive_paste.htm]http://sw-em.com/anti_corrosive_paste.htm[/url])on the connection before reattaching.

Use an ohmmeter to check lamp to ground (steel chassis) connections, but also don’t forget to check where steel members tie together (if bolted) to ensure the ground passes through.

You may want to run (recommended) a separate ground wire to each lamp, and connect it directly to the cable harness at the hitch.

Ray

Canada

The answer is simple: Fix the grounds. The reason that one light lights is that the one light that lights has the lowest resistance connection to the power source (brake light circuit in the car) and without a secure ground connection, the circuit through the lamp is completed through the filaments of all the other lamps back to ground.

Especially with boat trailers, you cannot rely on the metal frame of the trailer for a secure ground. Corrosion between the steel parts insulates them from each other. Similarly, you cannot rely on the trailer ball providing a good contact to vehicle ground. Therefore, you have to have a good source of ground in the vehicle to the trailer light connector and the connector on the trailer end should be firmly bonded to the trailer frame.

For best results, there should be a ground wire that connects to that same point on the trailer frame going to each light on the trailer.

George Andersen

New Port Richey, FL

Check the grounds first. Often, they use the trailer chassis as ground. When a ground pops loose, bulbs wind up in series that weren’t supposed to be, causing weird symptoms like you describe.

Chip Veres

Miami, FL

This sounds like a bad ground issue, indicated by other lights turning off when one turns on.

ince the frame is likely the common ground and not a separate wire, start with the ground connection where the wiring harness connects to the trailer. Also check the trailer/car connectors grounds. The lights may have a ground wire to the frame, or are grounded by the fixture mounting screws, check those screws, likely rusty.

Since it’s sometimes working, it’s a connection going bad or getting worse. Not surprising, considering they keep getting dunked in water.

Doug Arndt

Chicago, Il

Is it possible (or even necessary) to try to protect my "Smart" TV from hackers? If so, what are the issues and where is the best place to start?

#8163

Maurice Scalf

Brea, CA

Please log in to post an answer.

Answers

A Television set is a data receiving device (or a “Write-Only-Memory” as the joke that was distributed in the past) such that it has no useful data stored for a hacker to use. But if you are unsure about your home network security, then the first item to protect is the local network router, and then the Wi-Fi access point that your “Smart TV” connects to.

The best solution is simply disconnect the TV from the network, and use only local media sources (DVD,VCR, etc), or broadcast signals (antenna).

Raymond J Ramirez

Bayamon, PR

YES. Some Samsung and maybe even LG, TV’s have voice recognition and camera’s. Samsung even states in the users manual that their TV’s may capture personal room conversations of a private nature and transmit them to a third party.

Samsungs suggestion to prevent this is to turn off the audio capture feature (which would then prevent you from giving oral commands to your TV) and or unplugging the internet. A piece of tape over the camera would ensure your privacy here. You can read more here: www.theblaze.com/stories/2015/02/09/owners-of-samsung-smart-tvs-should-be-aware-of-this-very-scary-privacy-policy/

Ray

Vancouver, Canada

Is there a simple way to determine how long a given circuit will run on a standard 9V battery?

#8164

Janet Patel

Amarillo, TX

Please log in to post an answer.

Answers

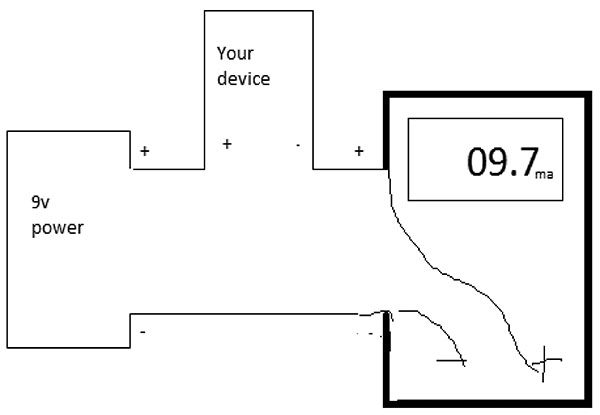

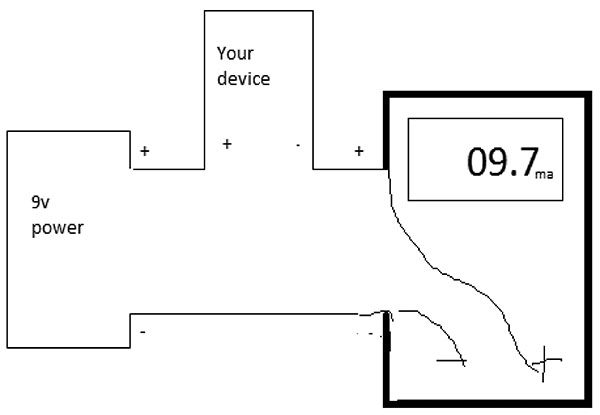

The load current you are drawing from your circuit and the time it will take to drain the battery is determined by the capacity of the nine volt battery you're using. How 'long' it will last as you expressed, is the circuit current your device circuit consumes. The average 9 volt battery capacity is given in milliamp hour rating -MAH. For common alkaline batteries it's about 500mah. Very simply 500 milliamps for one hour. This can be expressed differently but equally as half of one ampere for one hour. It's also is 25 mah for twenty hours, or 10mah for 50 hours. We simply divide 500 by your circuit's current load in milliamps, each milli-unit by the way is 1/1000 of an amp, to obtain the device load duration in actual time.

FIGURE 1

Unit measurement is important to understand realtionships in science and technology. You can find this load current draw - with your device, by using a digital multimeter -DMM, and power source like the actual battery, and some connectors. I like to use colored alligator jumpers, black to all marked negatives (see figure 1) and then all red to all positives. You don't have to color code this way but it helps to remember polarity. Set the meter to the high milliamp setting, most often 200 on low cost meters, just as long as it's well above your expected load. The current setting can be fragile for all meters since this test measurement might involve occasional large current, as in a SHORT or closed connective path which is 'shunted' through the meter's circuitry to express a current measurement. Thankfully it's fused. When I finish current settings by habit, I always reset my DVM or VOM to 20 volts or higher so I won't need to replace the fuses protecting the meter if I accidently measure too much current, on too low of a setting.

If you have a tech friend helping, you could also use their adjustable power supply. Set the battery voltage, hook up your device, (turn the device on!) and simply read the output current being used. Pretty much the easy way. Like you, I too like to know what current load various battery appliances use not only to predict run time, but also how big to the size up the battery if I wish. I use this setup alot.

I assumed for ease that the load you're device is using is steady and predictable. But maybe your load varies considerably. Time is constant, but the load fluxuates or turns on and off irregularly. You might proceed with some narlly math, but I'm more inclined to use our KILL-A-WATT type of household wattmeter - you have one don't you? Then plug in your power supply source set at 9 volts (but not from the battery) then read the watt-hour number over the time span you care to measure, then subtract the efficiency of the type of power supply your're using* from the total. I confess this is new for me. The Kill-A-Watt units are in 1/100 divisional units ie, amps, volts, except watt-hours is in tenths. Fair accuracy. I also have a WATTS UP like clone device that comprehensively continously measures DC power that is connected between a power source and it's load. Drone operators like these to monitor battery charging. Solar energy installations benefit from the detailed information they provide as well.

After experimenting with the AC wattmeter the Small switching xfmers show very small wattage unloaded. The estimated 10% loss isn't worth bothering to mention. Ferro-resonant laminated xfmers (wallwarts) on the other hand are hogs! an 800ma 12VDC unit drew 3.1 watts completely unloaded.

*The large and heavy laminate transformer wall-warts are about 60% efficient and the newer light weight and smaller high frequency switching transformers are up to 90% efficient. So in a very loose way you merely subtract the remaining percentage of the Wattmeter's total reading to fetch a general watthour reading. Length as you would say! Subtract from your total reading the percentage difference.

Michael Greenlee

via email

It depends on the device's current draw and its duty cycle, and on the battery type. For example, a 9-volt carbon-zinc (Leclanché), the "cheaper" batteries, are rated about 400 mA-hours, according to https://en.wikipedia.org/wiki/Nine-volt_battery.That theoretically means it could power a 1 mA load (e.g. 6,000 ohm resistor in series with a white LED dropping 3 V) for 400 hours, or a 10mA load (e.g. that same LED with a 600 ohm resistor) for 40 hours. These batteries do not have the same capacity for high currents, so they might provide 100 mA for only an hour or two.

The next step up in price are manganese-alkaline batteries, rated about 500 mA-hours. They are better in high-drain use, such as in a radio, and might provide 100mA for four or five hours.

Lithium-ion batteries are yet more expensive, and are rated at 1,200 mA-hours, but are intended for moderate- or low-drain applications. They have internal fuses to prevent high discharge rates.

In very low-drain applications, such as ionization-type smoke detectors or pace-makers, the battery life is limited by self-discharge, rather than by external current drawn. Alkaline batteries might last six years, and some lithium batteries are designed to last 10 years or more — obviously, it is not desirable to open up a patient to replace pacemaker batteries often. That said, it's often advised to replace smoke-detector batteries every six months. Use the old one in a radio, as it may still have some life left, but change them for safety.

Bart Bresnik

via email

if you know the current drain of your circuit, divide the amp-hour capacity of the 9V battery you're using by the current drain of your circuit to estimate the run-time (higher current drain = shorter run-time). Use the following capacities for "disposable" batteries as a guideline: 400 mAh (0.4 Ah) for carbon/zinc, 550 mAh (0.55 Ah) for Alkaline, 1200 mAh (1.2 Ah) for Lithium. Capacities for "Rechargeable" batteries range from 120 mAh (0.12 Ah) for NiCads to 520-620 mAh (0.520-0.620 Ah) for Lithium formulations. NOTE: your 9V battery is considered "dead" when its' terminal voltage drops below 5 VDC.

Ken Simmons

Auburn, WA

A standard alkaline 9V battery is rated at 550 mah. Theoretically, if the current drain was 1 mah, the battery would provide power for 550 hours. In reality, the are many factors that determine effective battery life besides current drain such as what is the lowest voltage that your circuit will run effectively?

Discharge rates are not linear so interpolation is not effective. Probably, the simplest way to determine battery life would be to breadboard the circuit, power it up and let it run until the circuit quits or the battery is exhausted.

Gene Sellier

Fairhope, AL

9 volt batteries are good for 400 to 500 milliamp-hours. So put the milliamp function of your multimeter in series with the battery and the circuit. Divide 450 by the number of milliamps you see to get hours. If the circuit is already built, snap one contact of the battery connector on the battery but leave the other one loose. Use the meter to complete the circuit.

Chip Veres

Miami, FL