The main problem with transformer design is the determination of the minimum number of turns for the primary. With too few turns, the transformer will overheat. Too many turns is only a problem if the turns will not fit within the “E-I” core windows.

We also need to determine what size of wire to use in the windings. With the aid of information extracted from Reference 1, we can design a power transformer having a 50 degree C temperature rise above ambient.

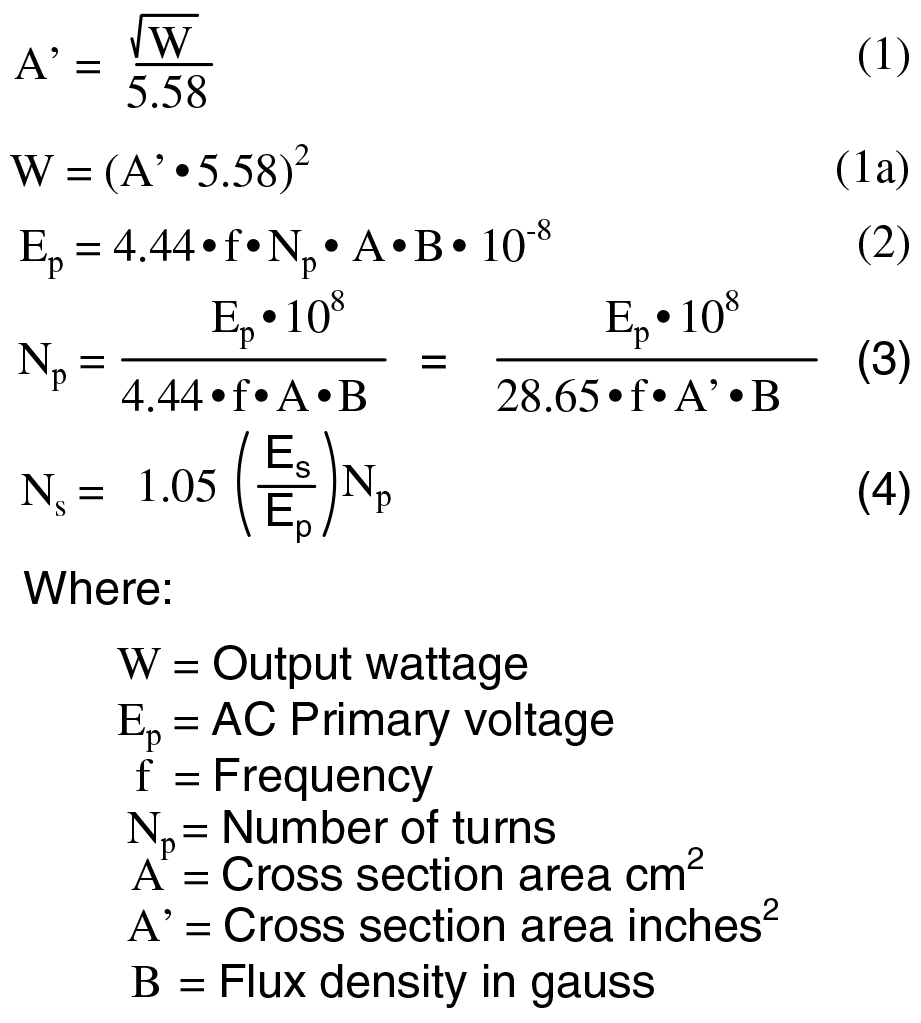

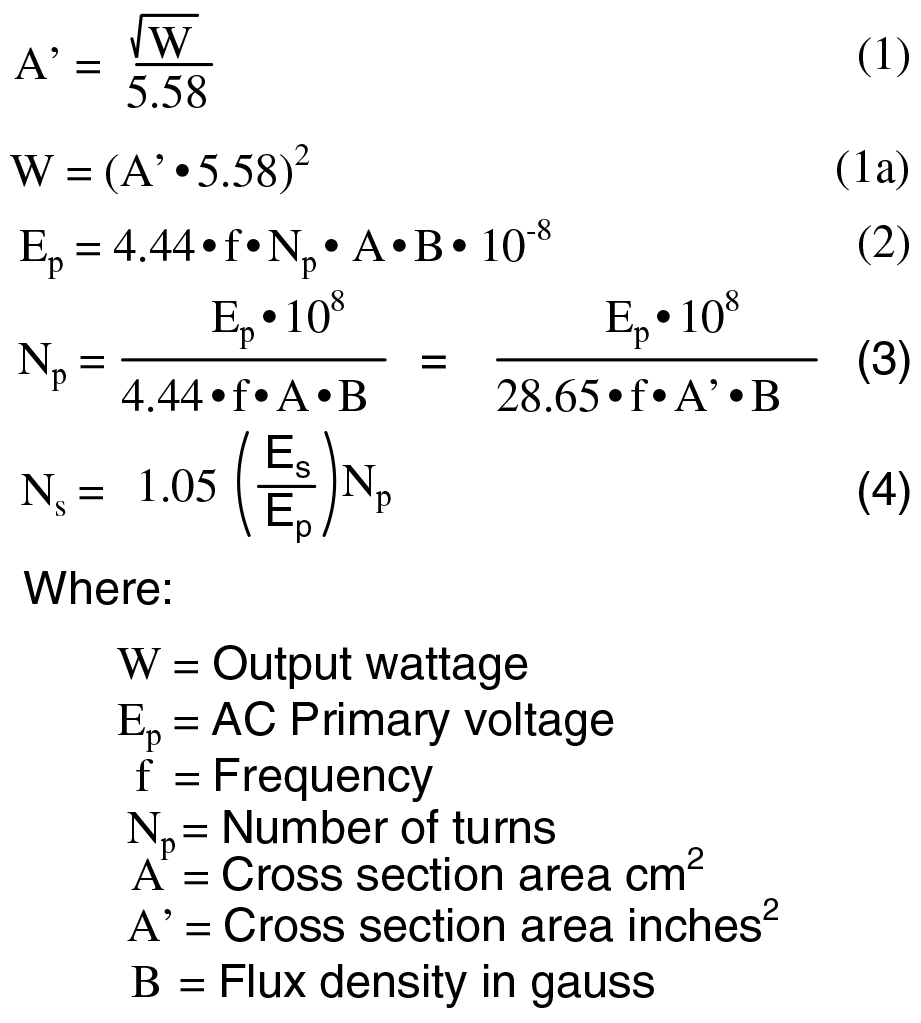

Figure 1

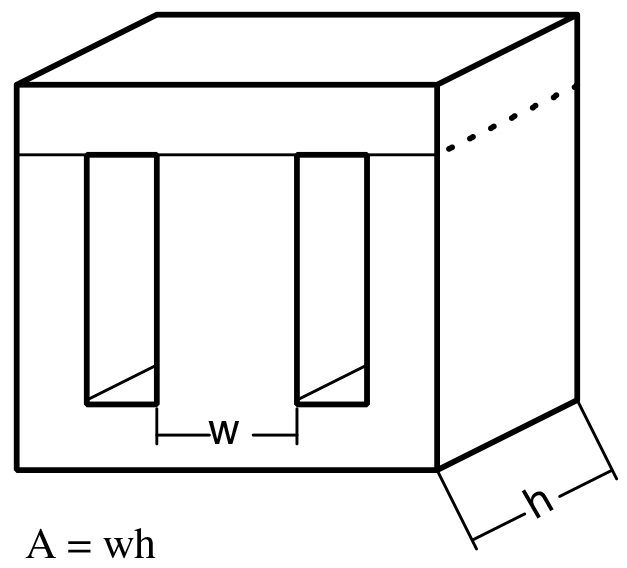

Use Equation 1 Figure 1 to estimate the size of the silicon steel laminated core required, given the wattage of your application. For example, a 12V 2.6A = 31.2W transformer requires a core with a cross section of one square inch (sqrt (31.2))/5.58 = 1.0. If you already have a core, multiply the height and width of the center leg to compute the cross section area as in Figure 2. Use Equation 1a to calculate the wattage rating of your core. The area will be A’ in Equation 3 if you measure in inches; A if measured in cm.

Figure 2

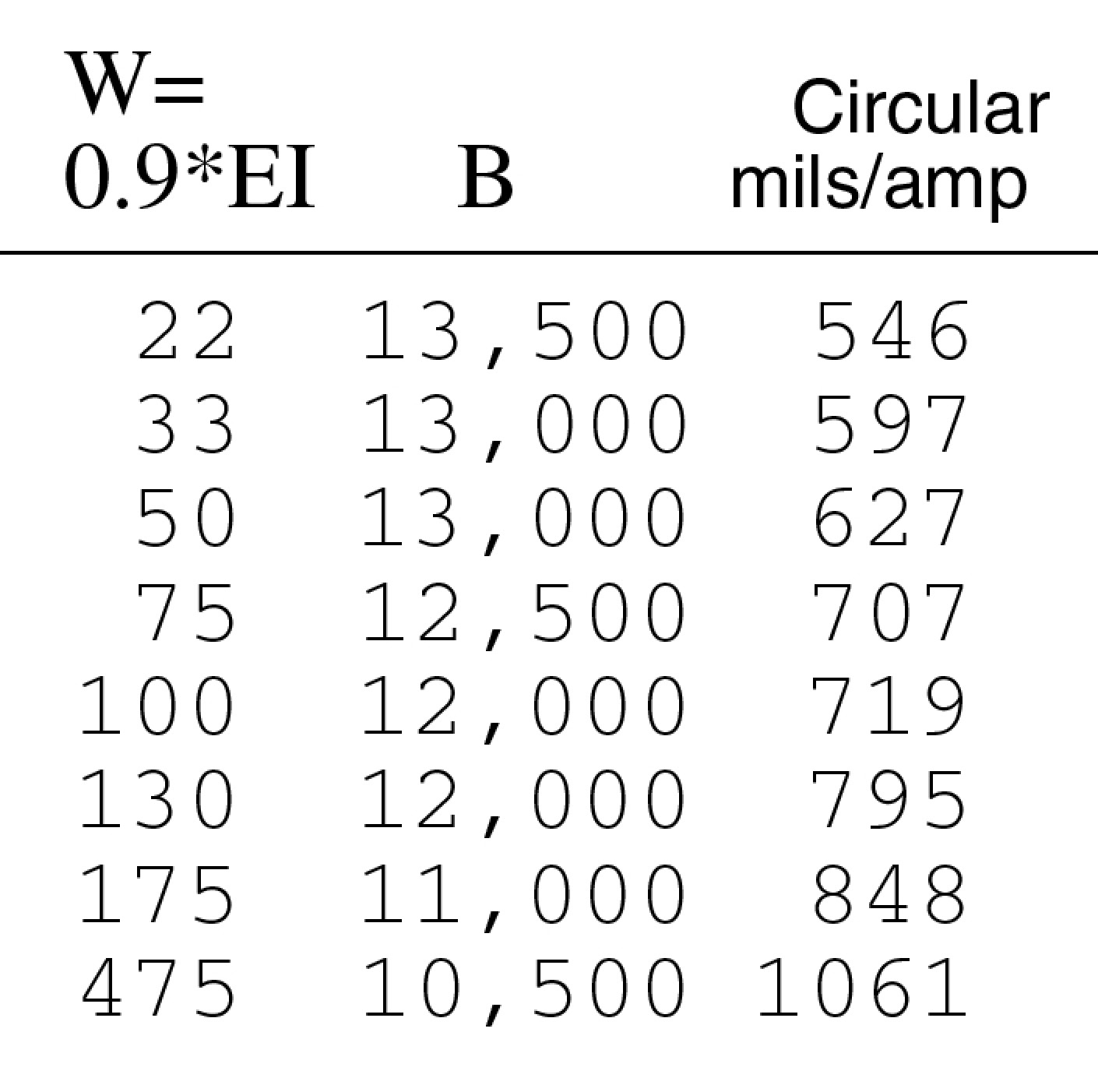

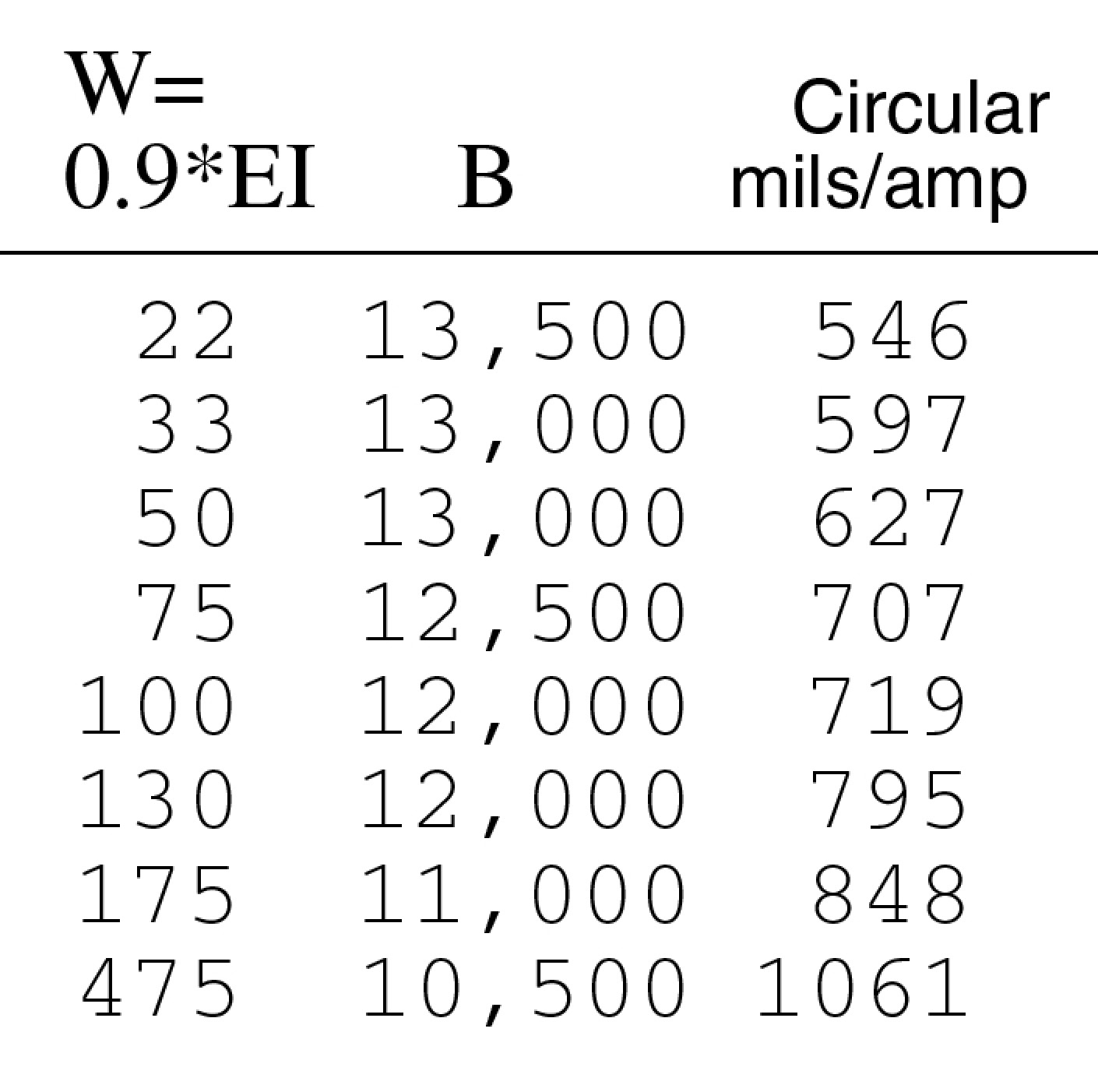

Equation 2 from Reference 1 was solved for Number of turns Np as Equation 3 The right-hand side of Equation 3 has a conversion factor applied to accept A’ in square inches instead of A in square centimeters. For our example as a 120 VAC 60 Hz transformer, set Ep=120, F=60, and A’=1.0. Consult Figure 3 for the recommended flux density B in gauss for the wattage of 31. Set B = 13,000. Equation 3: Np = 120(10e8) / (28.65)(60)(1.0)(13,000) = 537 turns.

Figure 3

Note that Equation 4 for Ns number of secondary turns has a 1.05 multiplier to account for winding resistance loss.

Continuing with our example, Ns = (1.05)(12/120)(537) = 56 turns.

The next problem is to determine what size wire to use for the primary and secondary windings. The size of wire depends on the wattage of the transformer. Small low-watt transformers dissipate heat more readily; thus, can get by with smaller wire size. Our 12V 2.6A = 31.2W example requires 597 circular mils of wire area per amp of current according to Figure 3. We need 597 * 2.6 = 1552 circular mils for the secondary wire. Looking up Reference 2, we find that 18 AWG wire has 1,624 circular mils of area; thus, 18 AWG for the primary. Since our primary/secondary turns ratio is 10/1, the primary current will be one tenth the secondary current (1/10)*2.6A = 0.26A. As with the secondary, we need 597 circular mils per amp. We need 597 * 0.26 = 155 circular mils for the primary. Consulting Reference 2, we find that AWG 28 has 160 circular mils for our primary winding.

Though I have not encountered any difficulty fitting the windings within the window space, you can estimate how much space will be required by consulting Reference 3 for turns per inch of a layer, and Reference 2 for wire diameter to estimate layer height. Use 90% of the turns per inch, 110% of wire diameter for layer height. Allow for thickness of the form on which the windings reside, allow for ends of the form, and insulation between the primary and secondary. Small diameter wire may require thin paper between each layer.

A complete re-wind of a transformer is only applicable to “E-I” cores that can be disassembled. Welded or epoxied cores cannot be disassembled. However, a few turns of a high-current secondary wire may be threaded through the window. According to YouTube videos, the secondary of a microwave oven transformer may be hacksawed and replaced with a few turns of heavy gauge wire.

Rather than a complete re-wind, consider re-using an existing primary by applying a custom secondary. Count the turns unwound from a known voltage secondary. Calculate turns per volt to aid in determination of the custom secondary turns.

- Reference Data for Radio Engineers, 4th Ed,1956, ITT, pp 275.

- Copper wire gauge table, www.ibiblio.org/kuphaldt/electricCircuits/Ref/REF_3.html#cuwire.tbl.

- AWG gauge vs. turns per inch, www.ibiblio.org/kuphaldt/electricCircuits/Ref/11099.png.