Want to be a treasure hunter? By discerning subtle changes in frequency, this design is capable of detecting coins to a depth of three to four inches.

The circuit can sense a soda can at a depth of six inches and metal pipes at an even greater distance. The unit is powered by two 9V batteries in series. The detector has a current draw of approximately 9 mA at 18 VDC. As a result, the batteries should last a long time.

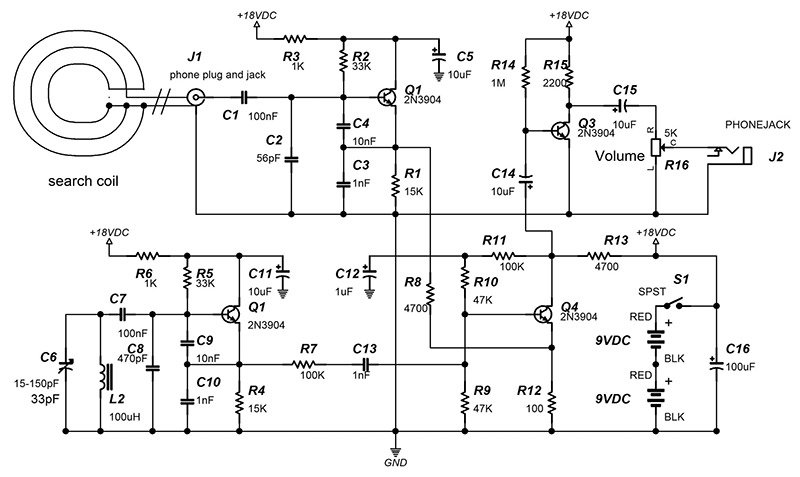

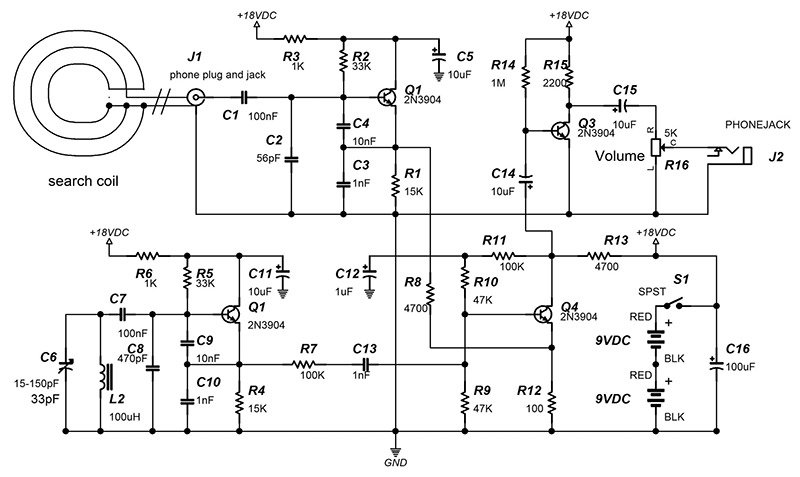

FIGURE 1. Four Transistor Metal Detector Schematic.

Theory

The design consists of four parts:

- Q1 forms an oscillator whose frequency is determined by L1.

- Q2 is a reference oscillator whose frequency is set by C6.

- Q3 is a mixer that multiplies the outputs of Q1 and Q2.

- Q4 is a simple one transistor amplifier.

L1 needs to be 100 μH. This inductor is created from 22 turns of 22 gauge magnet wire on a four inch diameter coil form (see Reference). However, I wound the coil with 21 turns, resulting in an inductance of 88 mH. The inductance measured into the phono cable with the search coil connected is 126 μH. In order to work properly, you must use the audio cable specified in the Parts List. The resonant frequency is F = 1 / (2π*SQR(L1*C)). C= 1 nF in series with 10 nF + 56 pF. Solving yields C = 965 pF. Calculating for F gives 456 kHz. Therefore, the oscillation frequency of Q1 is 456 kHz when no metal object is near the coil L1.

The oscillator formed by Q2 is the reference oscillator. This frequency can be changed by adjusting C6. The output must be set within 2 kHz of Q1’s output frequency. To obtain this result you may have to use a slightly different capacitor for C8. The part I used has a tolerance of ±20%. Note that the oscillation frequency of Q1 is very sensitive to stray capacitance.

The output of Q1 will vary about 70 Hz per each picofarad change of stray capacitance. Transistor Q4 forms a mixer. Q1 and Q2 both feed signals into this circuit. When a metallic object is close to the search coil, the inductance of L1 decreases. This causes Q1’s oscillation frequency to increase. The output of the mixer is the sum and magnitude of the difference of the two signals: Fosc + Fref and |Fosc - Fref| (where “|x|” means “absolute value of x”).

Suppose Fref = 500 kHz and Fosc = 501 kHz. The output of the mixer will be 1 kHz and 1,001 kHz. If Fref = 500 kHz and Fosc = 499 kHz, the output of Q4 is 1 kHz and 999 kHz. The frequencies output by the mixer feed a high input impedance BJT amplifier formed by Q3. The output of Q3 is capacitively coupled to the volume control R16.

The earphone used in this application must have a high impedance. The ceramic earphone specified in the Parts List has a 20 megohm impedance and works well. Note that both the high land low mixer frequencies are sent to the earphone. The earpiece shunts the higher frequency to ground, acting as a low-pass filter.

Construction

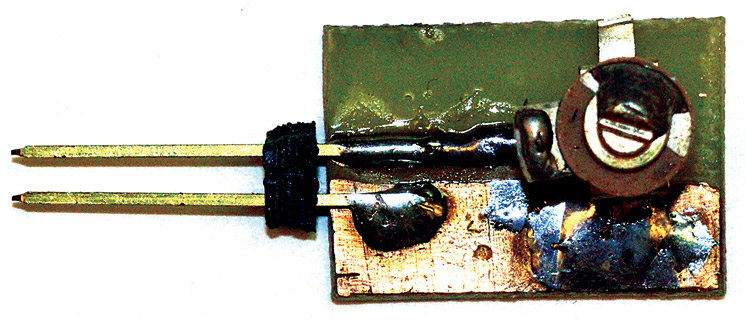

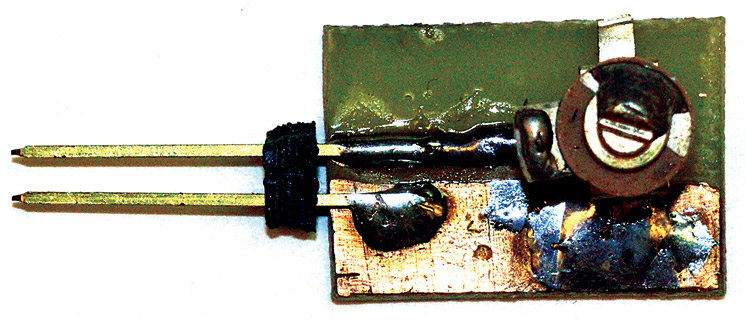

The circuit was built on a 2.6” x 3.5” piece of perfboard cut from PC board specified in the Parts List. Make a copy of the schematic and cross off the components as they are installed. An adapter was used to mount C6 (refer to Photo 1).

PHOTO 1. C6 Adapter PCB.

To construct the board, cut a 1/2” by 3/4” piece of double or single sided PCB material. Use a permanent marker to mask the areas where the traces should go. Then, etch the board and clean the ink off with rubbing alcohol. Finally, solder the capacitor and SIP pins to the PCB in surface-mount fashion.

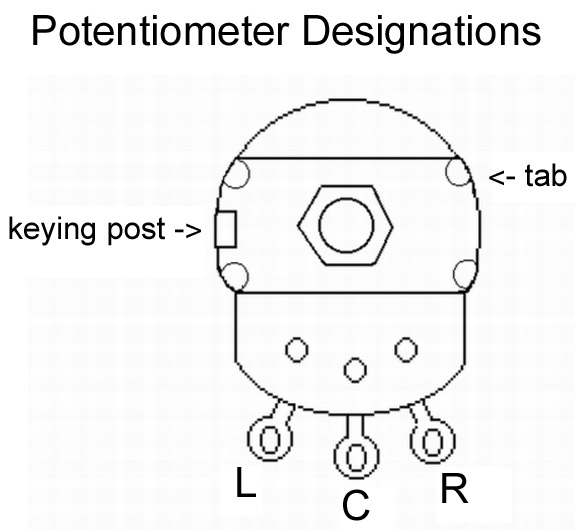

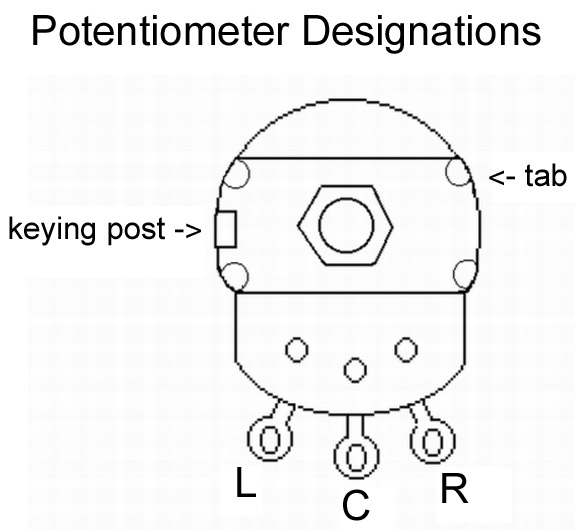

This adapter plugs into a two position SIP socket on the PCB. The pins of the adapter can be bent to 90 degrees for top adjustment. The volume control (R16) pin designations are shown in Figure 4.

FIGURE 4. Potentiometer pin designations.

\Break off the keying post of R16 with a pair of pliers. Instead of soldering the connecting wires directly to the PCB, .100” male headers are used. These headers are installed for the search coil, volume, S1, earphone, and 18 VDC. Female crimp housing connectors are used to make the twisted pair cable assemblies shown in Table 1.

| Source (Crimp Housing) |

# of Pins |

Destination |

Wire Type |

| COIL (L1) |

2 |

J1 RCA Jack |

Shielded Cable |

| VOL |

3 |

R16 |

Twisted Trio |

| EAR |

2 |

Phone Jack |

Twisted Pair |

| S1 |

2 |

SPST Switch |

Twisted Pair |

| 18 VDC |

2 |

9V Battery Snaps in Series |

Battery Leads |

TABLE 1.

Be sure to note the ground pin on the COIL, VOL, EAR, and 18 VDC connectors. An easy way to do this is to make the ground connections with a black wire in the cable assemblies. Keep the cable to the RCA jack as short as possible to reduce stray capacitance.

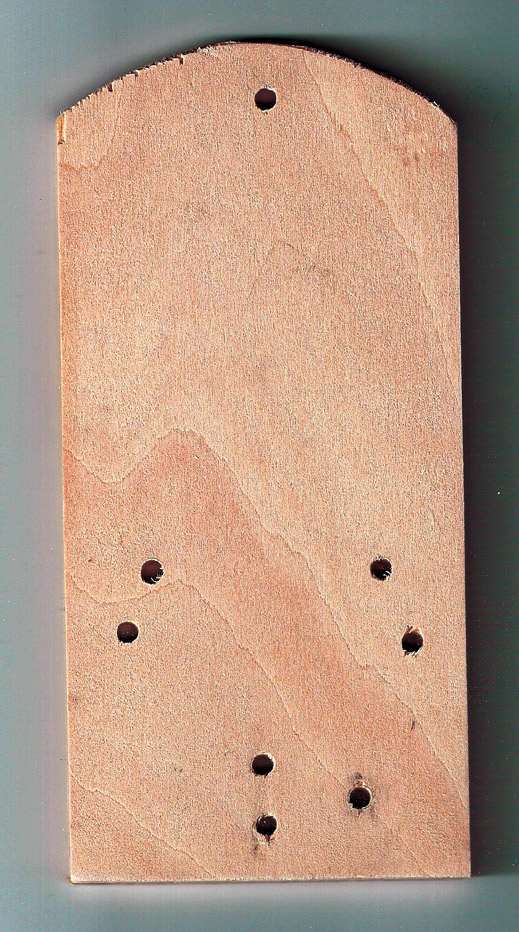

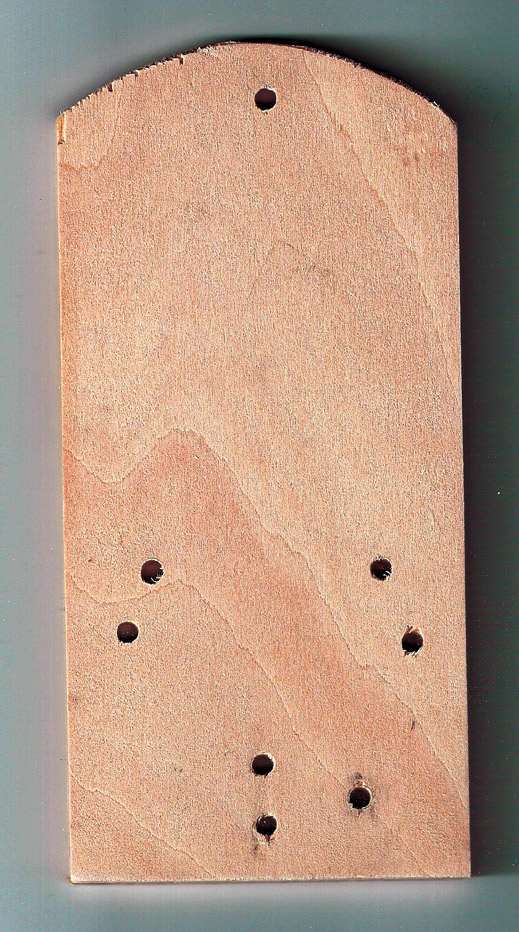

To construct the search coil, obtain a 1X copy of Figure 2 (Search Coil Form). Use the template to cut a form from the wood slat given in the Parts List. Drill the six holes 5/32“ in diameter.

FIGURE 2. Search coil form.

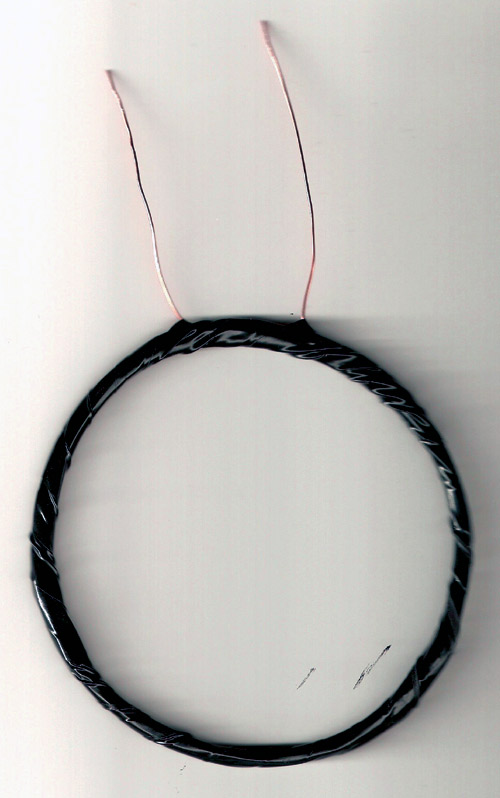

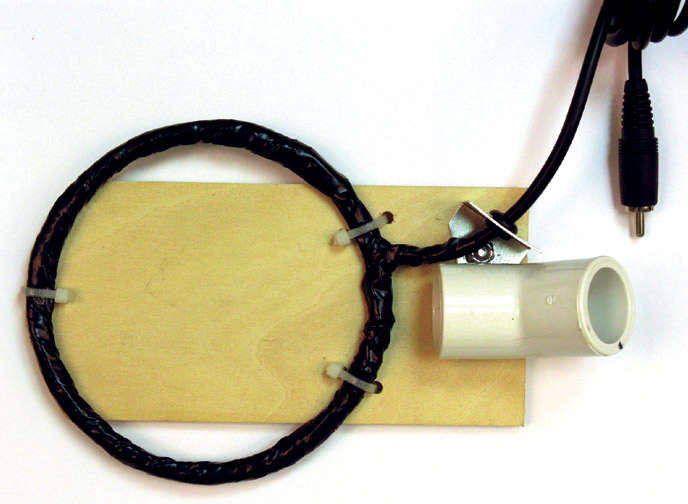

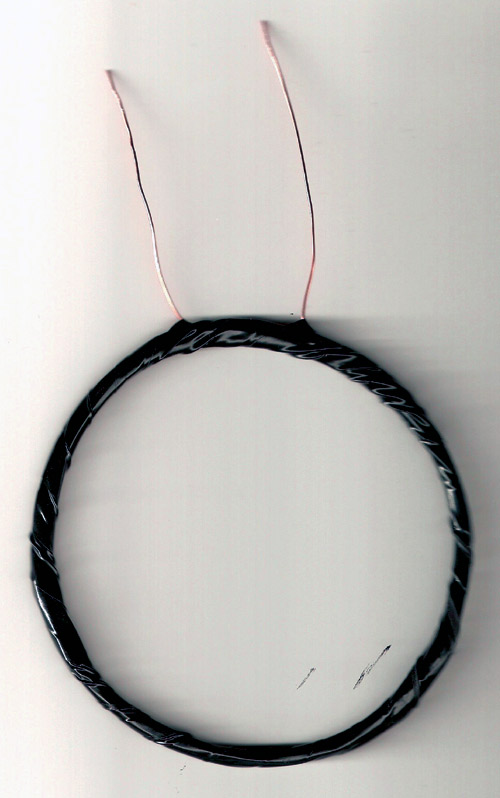

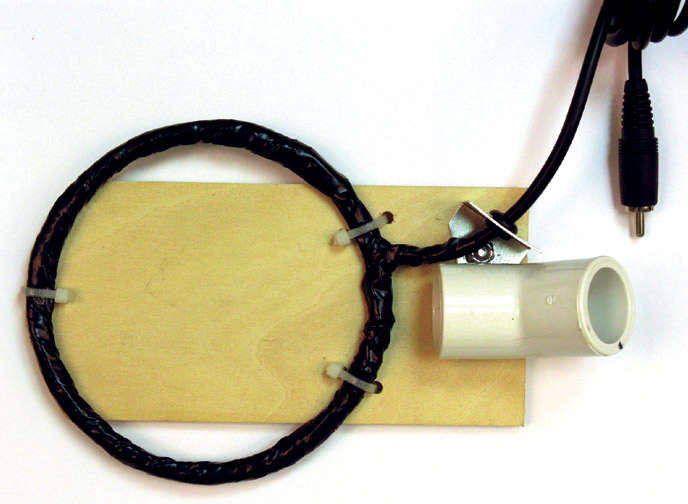

Now construct the wire coil. Wrap 21 turns of 22 gauge solid magnet wire around a 4“ diameter tube (an oatmeal container works nicely). Once the coil is wound, wrap it in electrical tape (see Photo 2).

PHOTO 2. Coil assembly.

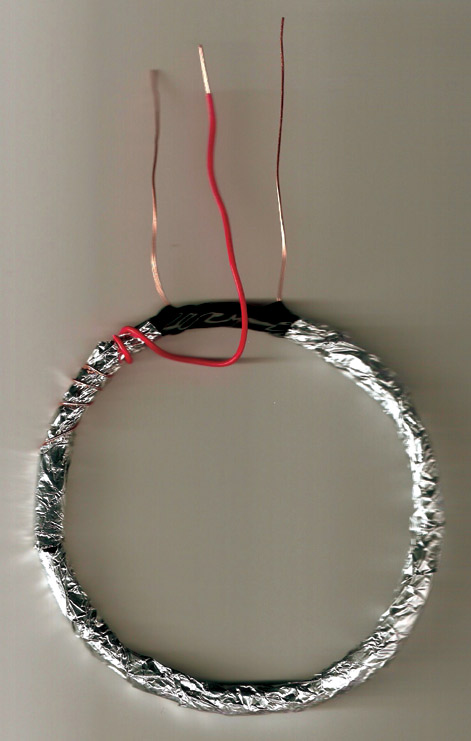

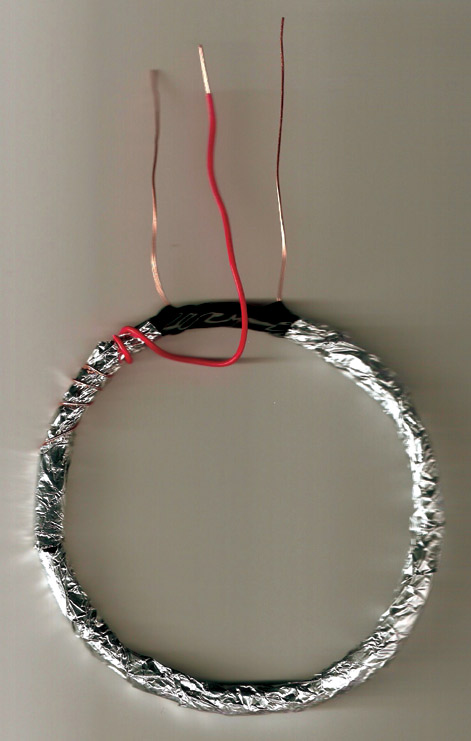

Wrap 1” strips of aluminum foil around the coil, leaving space for the two magnet wire leads. Strip three inches of insulation from a six inch red 22 gauge solid wire. Wrap the three inch bare end of this wire around the aluminum foil (see Photo 3). Wrap the whole coil assembly with electrical tape.

PHOTO 3. Shielded coil assembly.

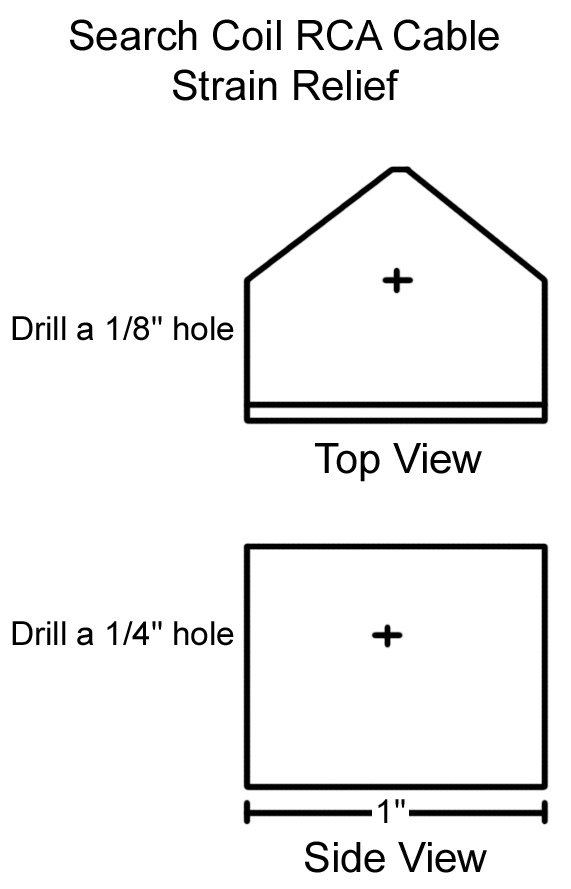

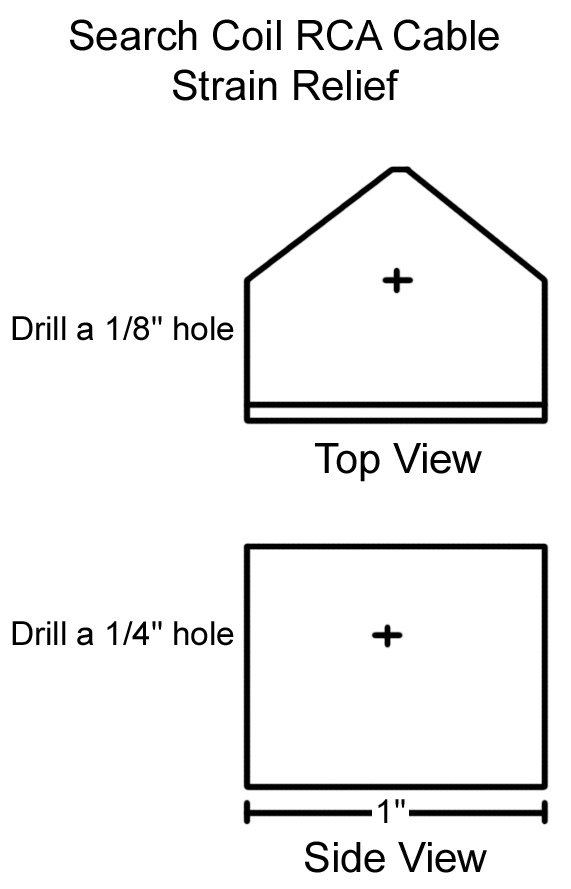

Make the search coil strain relief bracket from a piece of aluminum sheet (Figure 3).

FIGURE 3. Search coil RCA cable strain relief.

A 1/4” grommet is installed in the 1/4” hole. Cut off one end of the RCA cable and feed it through the grommet. Remove 1” of insulation from the end of the RCA cable. Cut the red wire from the search coil to 1/2” long and strip the insulation to 1/4“. Scrape the enamel from the magnet wires with a razor knife and tin with solder.

Solder the magnet wire adjacent to the red wire along with the red wire to the shield connection of the RCA cable. The other magnet wire is soldered to the center conductor of the RCA cable. The solder connections should be less than 1/2” and carefully wrapped with electrical tape or the output of the mixer may drift.

Next, mount the strain relief bracket to the wood slat with a 1/2” 6-32 machine screw, two external tooth lock washers, and a 6-32 nylon lock nut. The coil is mounted to the coil form with three wire ties. Finally, attach the 45 degree 7/8” inside diameter PVC elbow fitting to the coil form with two #6 x 1/2” sheet metal screws. You must first drill 3/32” pilot holes in the PVC joint to receive the screws. This 45 degree fitting receives one end of the metal detector shaft (a 33” long piece of PVC tubing).

A photo of the completed search coil assembly with the bracket is shown in Photo 5.

PHOTO 5. Search coil assembly with bracket.

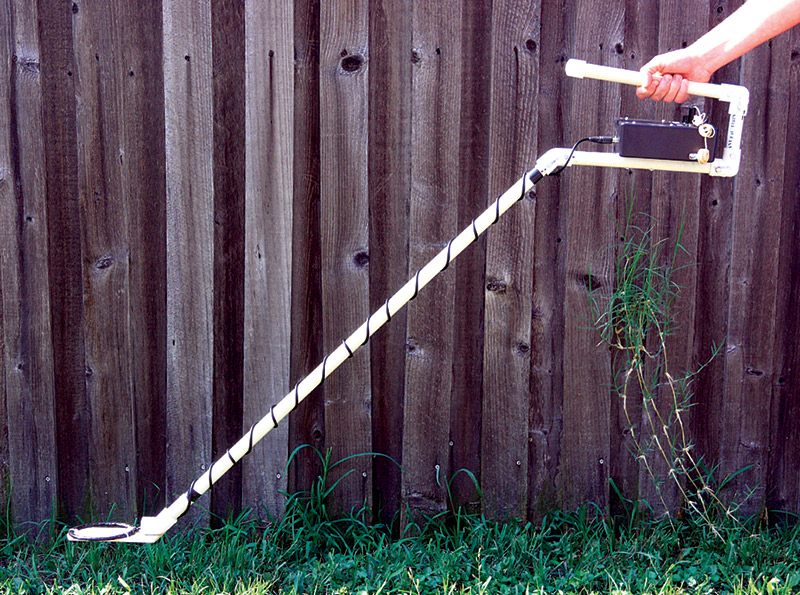

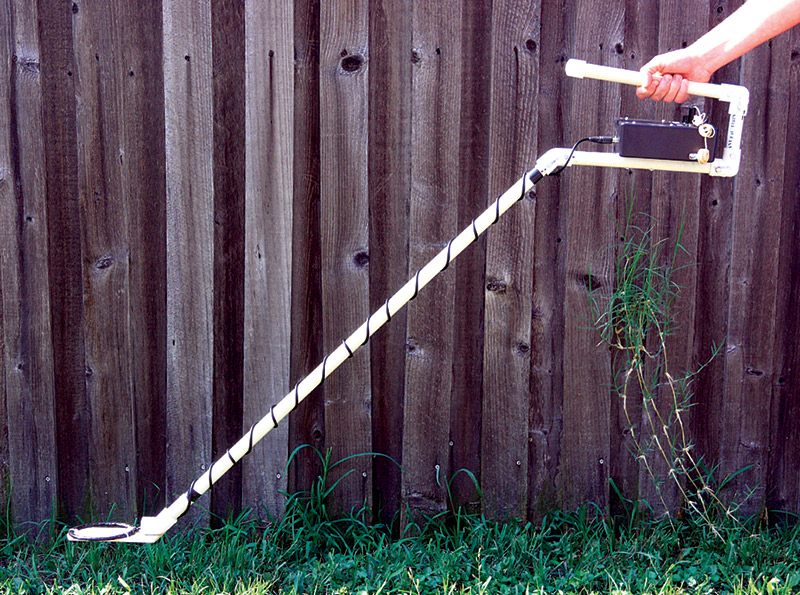

Two 10” and one 3.5” lengths of 7/8” diameter PVC pipe are used when making the handle for the metal detector. Refer to Photo 4 for assembly.

PHOTO 4. PVC handle assembly.

The handle uses two 90 degree elbows and one 45 degree elbow. Two 5/32” pilot holes and #10 1/2” sheet metal screws are used when connecting each of these elbow joints to the PVC pipes.

Drill two 5/32“ holes in the bottom of the case as shown in Photo 6. These holes are used to attach the enclosure to the handle assembly.

PHOTO 6. View of open case.

Use Photo 7 as a reference when mounting the following items to the front panel: J2, S1, and R16. Drill appropriately sized holes in the lid for these items.

PHOTO 7. Front panel view.

Next, drill a hole for J1 next to the 45 degree elbow joint where the 33” PVC pipe shaft attaches to the handle. Separate the lower and upper 10” lengths of PVC pipe. Drill mounting holes in the lower 10” piece of PVC pipe to match the holes in the bottom of the case drilled earlier and mount it with two 1-1/4” 8-32 machine screws, external lock washers, and nuts.

Install J2, S1, and R16 on the housing lid. Attach J1 to the case. Screw the PCB to the front panel with four nylon 4-40 1/2” threaded spacers and eight 4-40 screws. Connect the previously mentioned crimp housing cables between their sources and destinations. Attach the two 9V battery holders to the bottom of the case with double-sided adhesive tape.

Now, reassemble the upper and lower 10” PVC pipe sections. Insert the 33” main shaft into the handle assembly’s 45 degree elbow joint, drill a pilot hole, and secure with a #10 1/2” screw. The cap at the end of the handle is press-fit. Similarly, the search coil assembly is press-fit to the end of the 33” metal detector shaft.

Use

Once the PCB, search coil, housing, and handle assemblies have been made, follow these steps:

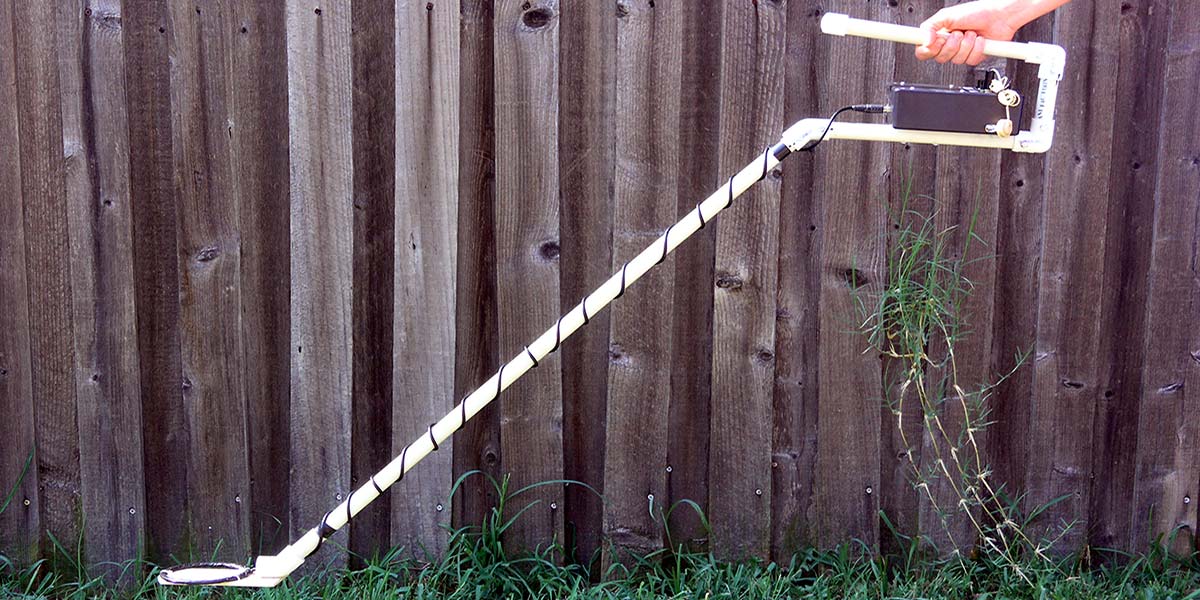

- Plug the RCA cable from the search coil bracket to the metal detector housing RCA jack. Wrap the excess cable in spiral fashion along the length of the metal detector’s shaft and secure with electrical tape. This will keep the cable from moving and causing a subsequent change in stray capacitance.

- Plug the ceramic earphone into J2.

- Turn the volume control completely clockwise.

- Attach the two 9V batteries to the battery snaps and install the batteries into the holders.

- Verify that S1 is in the On position.

You should hear a tone from the earpiece. The pitch at the earphone should increase when the search coil approaches a metal object. To obtain this result, make sure that no metal object is near the search coil and then turn C6 clockwise so that the pitch is a high tone, followed by a decreasing tone until the earphone is silent. Next, rotate C6 counter-clockwise until a frequency of approximately 2 kHz is reached. As mentioned before, if you are unable to tune the unit as specified, try reducing the value of C8.

Now that the tone has been set, attach the lid to the case with the four screws provided. If the metal detector does not balance properly, you may want to decrease the main shaft length to less than 33”. Photo 8 shows the finished metal detector.

PHOTO 8. Completed metal detector.

After the unit has been tested and completely assembled, it’s time to look for coins and jewelry! Good places to find coins at shallow depths are under the swings at a playground and below bleachers. For very large metal objects at close distances, the output pitch of the metal detector may be higher than physically audible. Happy hunting with your four transistor metal detector! NV

Reference

R. Dean Straw, N6BV, The ARRL Handbook, “Calculating Practical Inductors,” 1999, p. 6-22, The American Radio Relay League.

Parts List

| ITEM |

DESCRIPTION |

|

|

| R1, R4 |

15K 5% 1/4W |

|

|

| R2, R5 |

33K 5% 1/4W |

|

|

| R3, R6 |

1K 5% 1/4W |

|

|

| R7, R11 |

100K 5% 1/4W |

|

|

| R8, R13 |

4.7K 5% 1/4W |

|

|

| R9, R10 |

47K 5% 1/4W |

|

|

| R12 |

100 5% 1/W |

|

|

| R14 |

1M 5% 1/4W |

|

|

| R15 |

2.2K 5% 1/4W |

|

|

| R16 |

5K audio taper pot |

|

|

| C1, C7 |

100 nF 50V ±10% |

|

|

| C4, C9 |

10 nF 50V ±10% |

|

|

| C3, C10, C13 |

1 nF 50V ±10% |

|

|

| C2 |

56 pF 100V ±20% |

|

|

| C8 |

470 pF 100V ±20% |

|

|

| C5, C11, C14-15 |

10 µF 50V ±20% |

|

|

| C12 |

1 µF 50V ±20% |

|

|

| C6 |

15-150 pF variable cap |

|

|

| L1 |

See text |

|

|

| L2 |

100 µH ±5% |

|

|

| Q1-Q4 |

2N3904 transistor |

|

|

| J1 |

RCA jack |

|

|

| J2 |

3.5 mm phone jack |

|

|

| S1 |

SPST switch |

|

|

| Aluminum sheet |

K&S Metals |

|

|

| Wood slats |

Forster 6-Count Slats |

|

|

| PVC pipe |

6’ 7/8” OD PVC Pipe |

|

|

| Audio cable |

6 ft cable |

|

|

| Case |

6 x 4 x 2 |

|

|

| Battery snap |

9V snap (2) |

|

|

| Earpiece |

Ceramic earphone |

|

|

| PCB |

Prototype board |

|

|

| Battery holder |

9V holder (2) |

|

|

| Tape |

Two-sided adhesive tape |

|

|

| Batteries |

2 x 9 VDC |

|

|