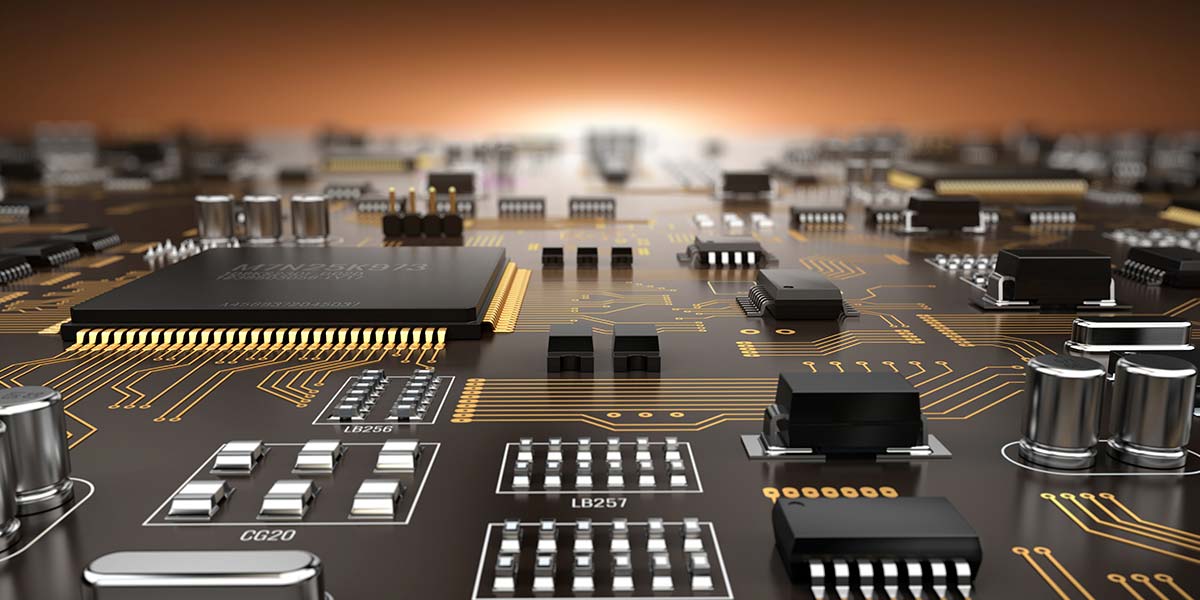

A microchip is a synonym for chip, which is common slang for "integrated circuit." Why the term "chip?" Because when you slice a wafer of integrated circuits into their individual parts, they look like, well, chips. They used to anyway, because the first ones in the 1980s were much smaller than many of the chips today. However, there are still tiny chips made in 2020, and also much bigger ones about the size of a postage stamp and even larger. Hard as it may be to believe, a postage stamp is 100 times thicker than the active layers on the chip. There are all kinds of chips, and the major ones are outlined below.

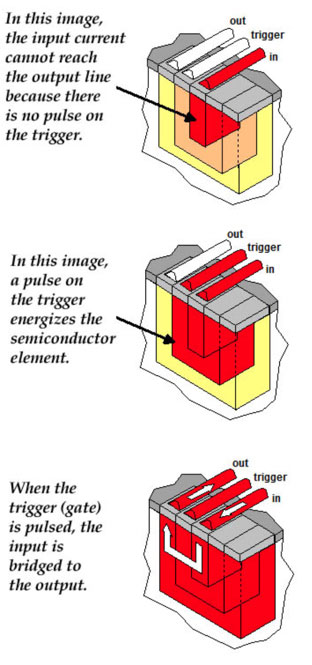

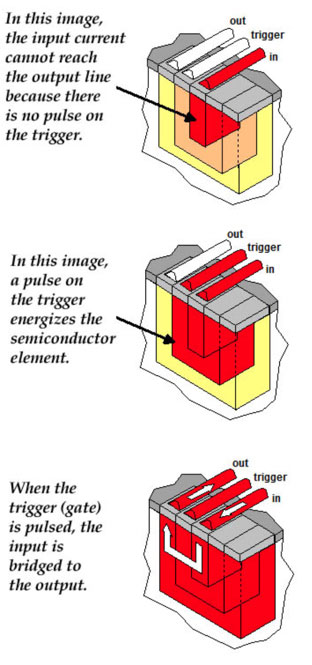

The fundamental component of a chip is the transistor, which is like a light switch on the wall. It allows current to pass through or not, depending on the position of the toggle. Except on a transistor, the toggle is a pulse of electricity. The pulse closes or, in some cases, opens the line. Transistors are wired in patterns (series, parallel, etc.) that conform to the rules of Boolean logic, which make up all the digital circuits.

Today, there are chips with as few as 50,000 to more than 30 billion transistors. And, in fact, if you count all the transistors in all the chips ever made since the 1970s, more than 10 sextillion transistors have been manufactured. To clarify, sextillion is a billion times a trillion. That makes the transistor the most manufactured thing in the history of the world. Well, maybe M&Ms exceed that number, but we're talking electronics here.

A transistor is like a light switch. Except in this case, the toggle switch is a pulse of electricity. When the transistor is pulsed, it allows current to pass through the semiconductor material.

CPU

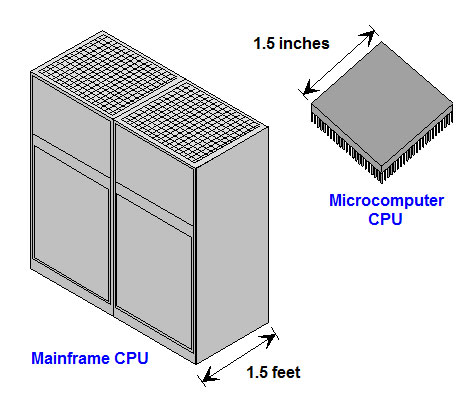

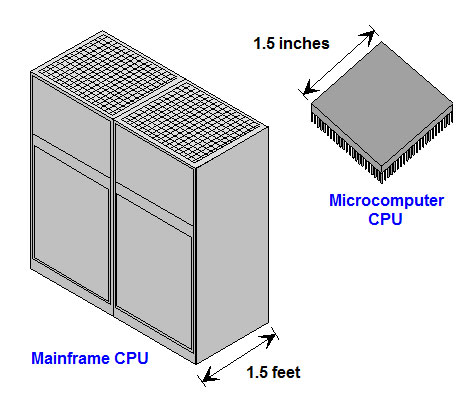

There is quite a variety of chips on the market, but the central processing unit (CPU) is what most people have heard of. There's a CPU chip in every computer and mobile device, which is the basic execution unit that follows the instructions in the software. In essence, the CPU in every computer is what follows instructions fed into it, and without a CPU, it can hardly be called a computer.

CPUs. Every computer has a CPU that executes instructions. Mainframes also use chips, but the entire cabinet was called a CPU from day one.

RAM and Storage

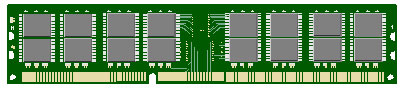

The computer's random-access memory (RAM) is where all processing takes places, and RAM chips are used in nearly every electronic computing device on the planet. Although storage used to be magnetic disks and magnetic tapes before that, today storage is commonly Flash memory chips. Your USB drive is a Flash chip, and chances are your laptop uses a solid-state drive (SSD) comprising Flash chips.

Memory module (dynamic RAM).

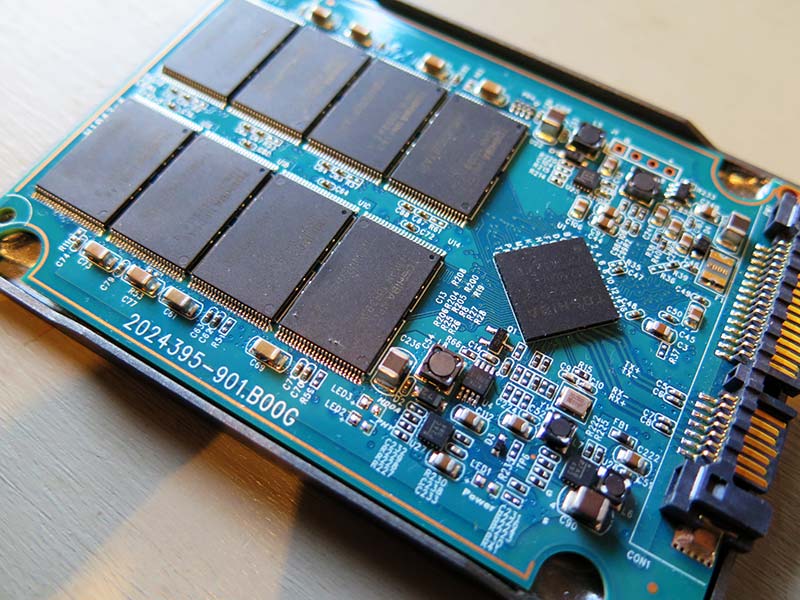

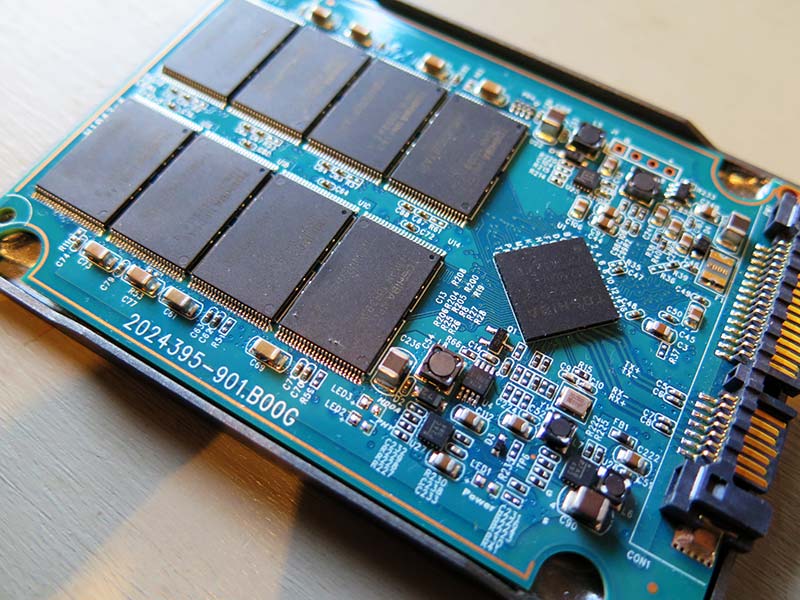

Flash memory – SSD. The case on this SSD is opened to expose the chips. Outside of their packages, all chips look alike, but RAM and Flash memory work differently. RAM is volatile, while Flash memory chips hold their content.

MCU

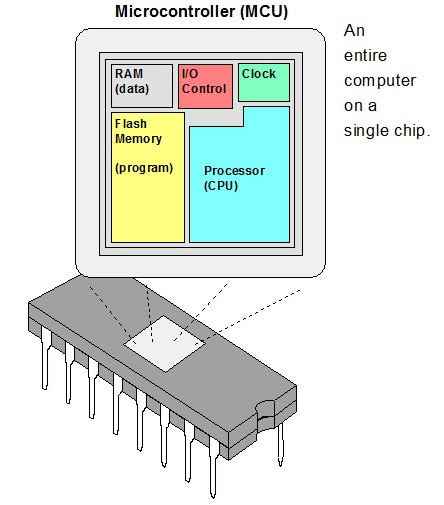

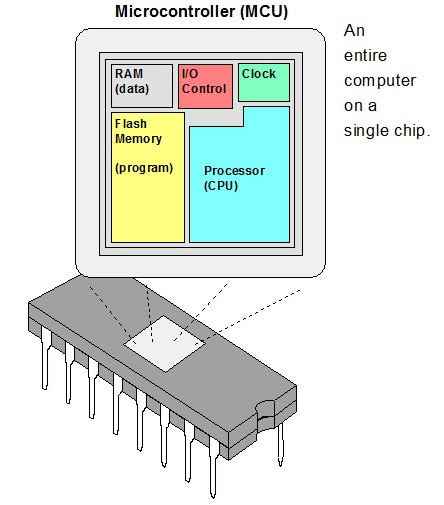

A microcontroller — or microcontroller unit (MCU) — is called a "computer on a chip." It has a CPU along with RAM, storage, and input/output circuits. Billions of MCUs are made every year because they're in everything from your kid's stuffed bear to your toaster. In fact, there can easily be more than a hundred in your new car.

MCUs are "not" state-of-the-art because they don't need to be. They can cost as little as 50 cents or as much as a couple bucks, but the interesting thing is the myriad applications that use them. For some time now, when designing an appliance, it’s cheaper and faster to employ an MCU instead of designing a dedicated electronic or mechanical device to do the most menial things such as turn the unit on or off.

An MCU can reside in your new car waiting for you to open the door so it can turn the interior lights on, then wait for it to close so it can count 15 seconds and turn the lights off.

Imagine back in the 1950s looking at the room-sized UNIVAC I, which shocked everybody when it predicted Eisenhower's election landslide ahead of the final count, that somebody said "in the future, everything you see in this room will be no larger than the head of a pin and be used to turn your coffee maker on."

Microcontrollers (MCUs). Used in thousands of products, billions of MCUs are made every year.

GPU

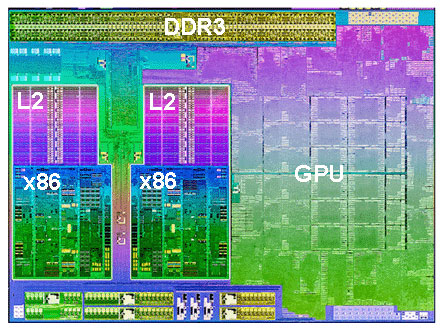

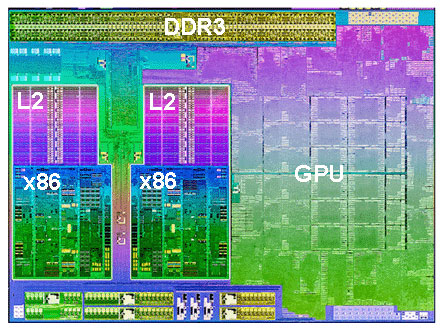

Graphic processing units (GPUs) are the chips responsible for rendering the images seen on screen. They contain hundreds of parallel processing units for converting a frame of data into a matrix of screen pixels. GPUs may also include fast ray tracing, which computes how a light source generates bright and dark areas on objects for total realism.

A fast GPU is the heart and soul of a gaming computer, and top-end cards can cost more than the computer itself. Because of their parallel processing capability, GPUs are also used for AI and other math-intensive applications.

An integrated GPU. This Trinity chip from AMD is a dual-core CPU and GPU on the same chip. GPUs are often integrated like this example, but they are also widely available as stand-alone cards. (Image courtesy of AMD; www.amd.com.)

SoC

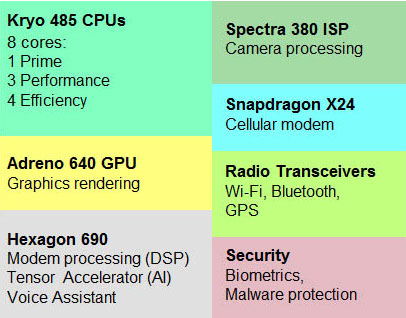

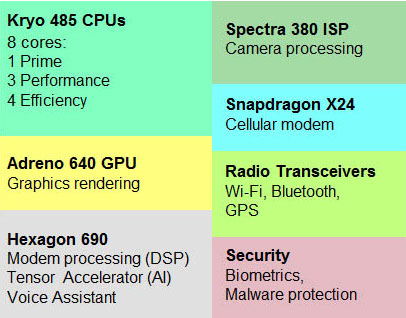

Increasingly, more circuits are built onto a single chip, eliminating the need to interconnect multiple chips. The system-on-chip (SoC) -- which is in every smartphone -- combines the CPU with the GPU. RAM and storage may also be included, as well as coprocessors for mathematical processing.

Wi-Fi can also be built in. SoCs contain billions of transistors, and these are the chips that get the most attention. When you consider everything they do, it’s really quite a miracle.

A very comprehensive SoC. Used in Android phones, Qualcomm’s Snapdragon 855 contains all the processing capabilities required in a modern smartphone, including graphics and AI processing.

FPGA

A most unique chip is the field programmable gate array (FPGA) which is "programmable hardware." Whereas every CPU executes instructions contained in the software, an FPGA "re-wires" its own logic circuits depending on the map of connections that is loaded every time it starts up.

Why this type of chip? Because hardware is always faster than software. A CPU has to fetch the next instruction, interpret its purpose, and then do it. The circuits in an FPGA are automatically rewired every time to just do it.

FPGAs are used to test out a new chip design and even get products to market faster because it takes time and a lot of money to design new chips from scratch. They are also used in production environments whereby speed is needed but processing requirements are constantly upgraded — a not uncommon occurrence.

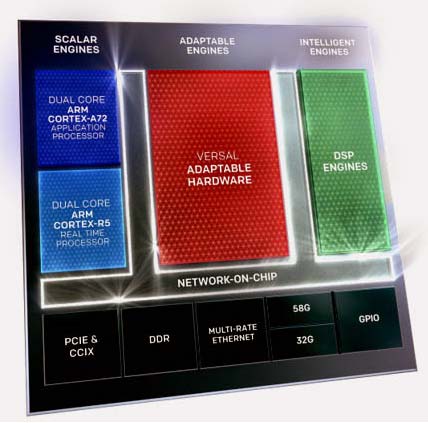

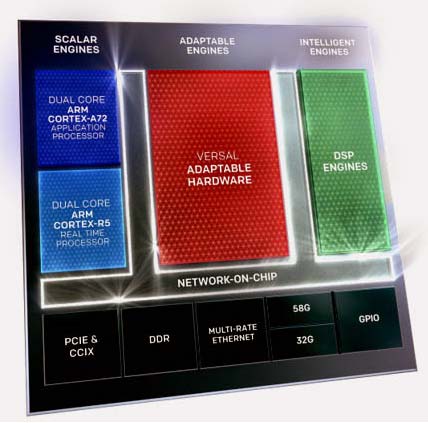

An extremely comprehensive FPGA. Xilinx’s Versal ACAP chip includes programmable logic (center) along with two ARM CPUs, input/output controllers, and digital signal processing (DSP) engines for mathematical processing. Containing more then 30 billion transistors, this unique chip is highly customizable for different applications such as AI and cryptocurrencies. (Image courtesy of Xilinx; www.xilinx.com.)

AI Accelerators

Artificial intelligence (AI) is the hottest buzzword in the industry today because every industry is attempting to use it in some manner or another. Highly successful in pattern recognition (faces, speech, etc.), AI is increasingly used to discover unknown relationships as well as enhance decision making.

The backbone architecture of an AI application is the neural network, which loosely resembles the neurons and interconnections in the human brain. AI accelerators are custom designed to execute the inference engines which are the neural networks in action, coming up with answers. No matter what the purpose the networks were designed for, custom AI chips speed up the exorbitant number of mathematical processes taking place in the many parallel connections.

Microchip Technology, Inc.

A very nice thing about Microchip Technology is that it’s an American chip manufacturing company located in the Phoenix, AZ suburbs. The US is the leader in the semiconductor industry (official name of chip manufacturing) with companies such as Intel, Qualcomm, Micron, and NVIDIA. However, Microchip is not widely known to the average person, yet chances are one of their chips is executing instructions in one or more of your appliances, power tools, or some other product you use every day.

Originally a spin-off of General Instrument in 1987, Microchip became independent two years later. The company makes several types of chips, including CPUs, MCUs, and analog and digital chips for a variety of industries. It even makes radiation hardened chips for aerospace. However, Microchip is widely known for its PIC line of microcontrollers (MCUs) and billions have been shipped. With a very extensive product line, the company's home base is in Chandler and Tempe, AZ with facilities in Oregon, Colorado, Thailand, and the Philippines.

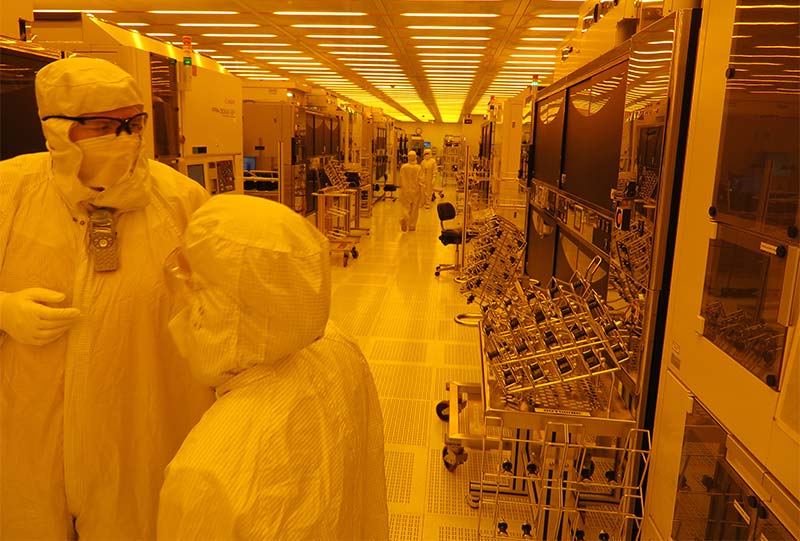

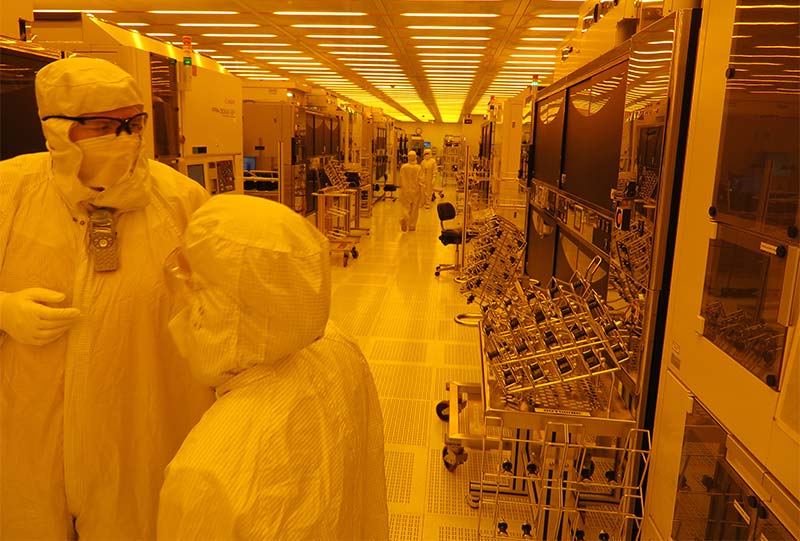

Early in 2019, I had a tour through Microchip's Chandler plant, and it was quite an education. Suited up in clean room garb, the claustrophobia I felt for the two hour tour was well worth it.

All suited up. Alan Freedman and Microchip PR specialist, Christie Haber just needed nylon gloves to start the tour.

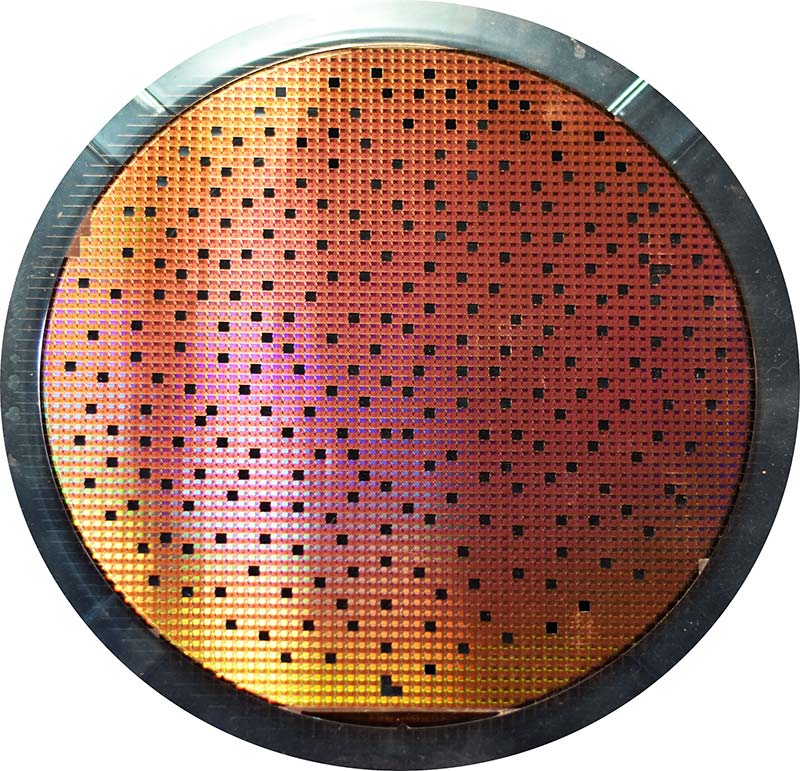

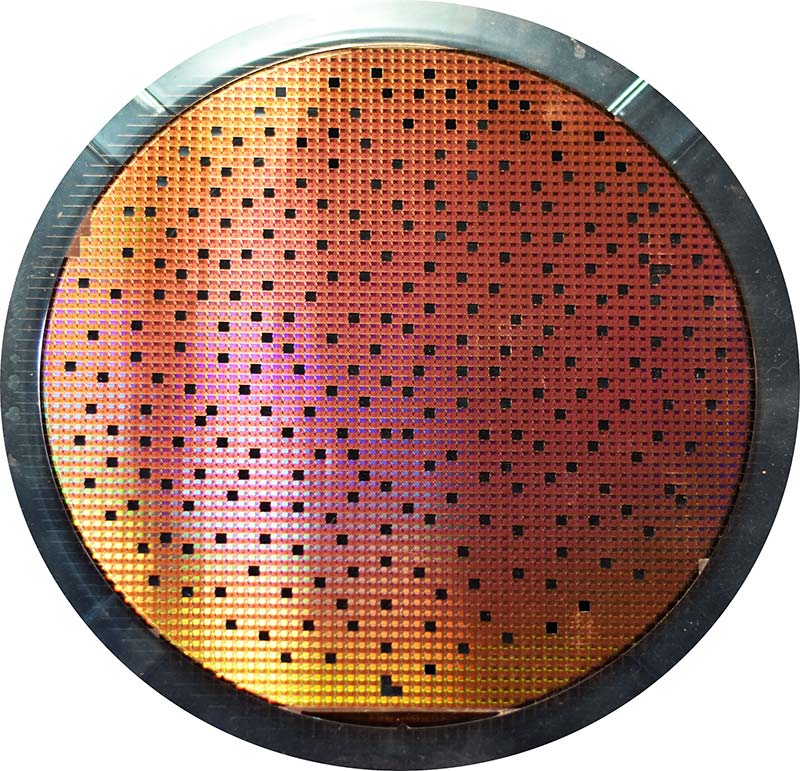

All chips are made on thin slices of silicon (called wafers), four to 12 inches in diameter. There can be thousands of chips on a single wafer, and all the transistors on all the chips are fabricated at the same time.

The transistor's elements are created layer by layer, and there can be a dozen or more layers and many steps in the operation. The entire process can take days, weeks, and even months, depending on the type of chip. That was eye-opening for me as I would guess it would be for most people, because chips are so blindingly fast one might think they’re also manufactured in a split second. Hardly the case.

Microchip's chips are state-of-the-art for microcontrollers, but their construction process is not because it doesn't need to be. The latest high-performance CPUs from Intel, the SoCs in the newest smartphones, and the fastest NVIDIA GPUs gamers salivate over are the chips that get all the attention. They're the ones with billions of transistors that keep getting denser and denser, so more circuits can be placed on a single chip.

People want more functions on their smartphones, and they want them thinner and lighter. Gamers want more rendering speed for realistic action. Fortunately, your coffee maker works just fine with an MCU from Microchip that was built with semiconductor process technology dating back to the 1980s and 1990s. Otherwise, the price of your toaster would cost you an additional hundred bucks, and your toddler's $15 gadget would be $115.

Manufacturers of toys, electronics, and other gadgets want more capability built in and want to keep the retail prices low, which is why billions of MCUs fit the bill perfectly and why Microchip keeps pumping them out like hotcakes. A Microchip MCU can cost way less than your pancake stack at iHop; only a couple of dollars. In fact, as little as 50 cents.

A test wafer full of PIC25 microcontrollers from Microchip. Chips were taken out of this wafer and checked for uniformity. A closeup (top) shows the bare chips and the ones that were removed for testing.

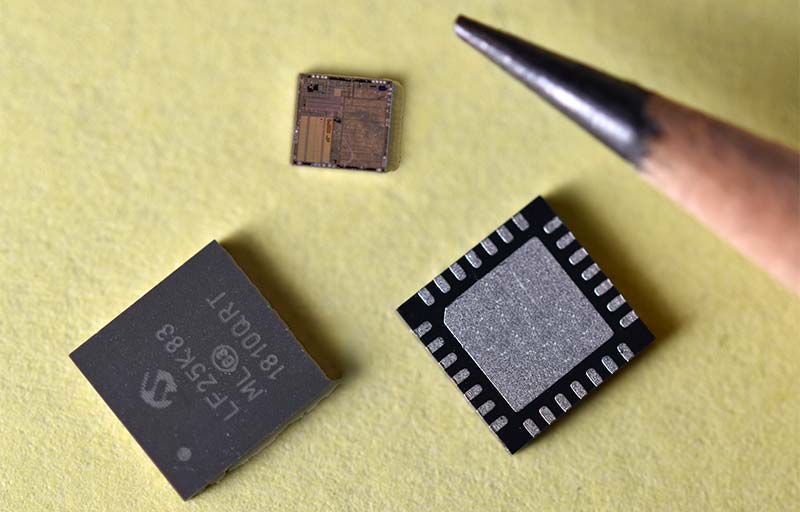

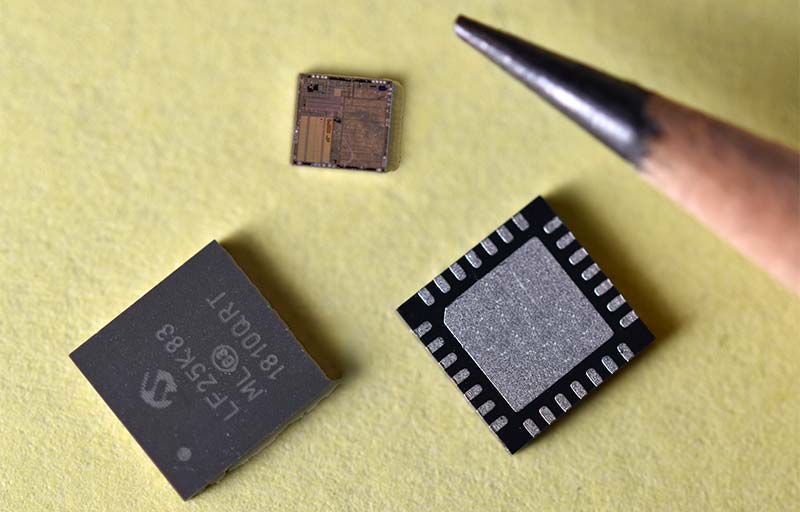

The PIC25 microcontrollers ready for mounting. This shows a bare chip (bare die) and the package they are mounted in for placement on a circuit board.

A part of the UNIVAC I being delivered in 1956. In today’s dollars, a UNIVAC I cost $12 million, which could buy about five million Microchip microcontrollers, or 24 million of Microchip’s smallest chips, and each chip would be far more powerful than the UNIVAC I. Imagine you were watching this scene in 1956 and someone next to you said, “You know in the future, everything you see now will be so small it could be placed on the tip of your finger.” What would you have said back then?

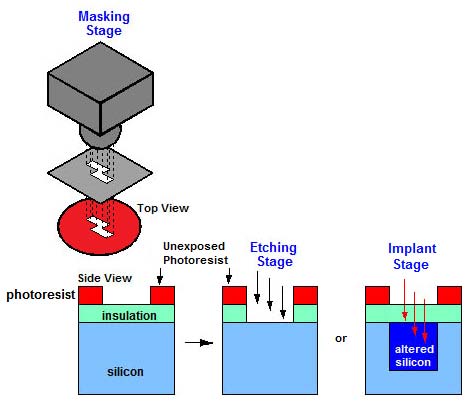

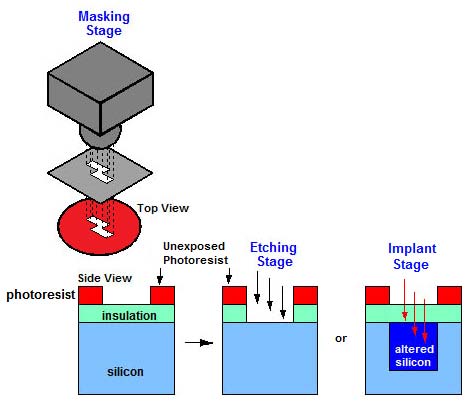

Transistors are made using lithography. Wafers are coated with a photo resist, and patterns are created by exposing the wafer to ultraviolet light through a photomask. The unexposed areas are etched away allowing chemicals to be deposited beneath the surface. The layers are created one photomask at a time.

Microchip photomask library. The transistor and circuit patterns are applied to each layer by shining light through photomasks. Chips require from seven to 40 or more photomasks to create the necessary layers.

Microchip’s facilities. All the machinery required to make chips is highly specialized. You don’t find this stuff at Home Depot!

All operations are on wafers. Wafers somewhat resemble vinyl records and old-fashioned juke boxes (remember them?). The bottom image is a heating stage for the wafers.

No ultraviolet wavelengths. The photo resist used to coat the wafers is very light-sensitive, and various staging areas use lighting that has the UV wavelengths stripped out.

Conclusion

I hope you've enjoyed learning more about the amazing microchip. Who knows. Perhaps future generations looking back will be amazed at the "large" size today's chips have to be. NV

Specs for the PIC18F25K83 Microcontroller (MCU)

| Program Memory Type |

Flash |

| Program Memory Size (KB) |

32 |

| CPU Speed (MIPS/DMIPS) |

16 |

| SRAM (B) |

2,048 |

| Data EEPROM/HEF (bytes) |

1024 |

| Digital Communication Peripherals |

2-UART, 1-SPI, 1-I2C |

| Capture/Compare/PWM Peripherals |

4 CCP |

| Timers |

3 x 8-bit, 4 x 16-bit |

| ADC Input |

24 ch, 12-bit |

| Number of Comparators |

2 |

| Number of CAN Modules |

1 CAN |

| Temperature Range (°C) |

-40 to 125 |

| Operating Voltage Range (V) |

1.8 to 5.5 |

| Pin Count |

28 |

| Low Power |

Yes |