I built a Jeopardy game console for use in a classroom setting. The console works quite well and can accommodate up to four players or teams. The issue I have is that the player buttons are attached to the console via cables and this gets cumbersome in class. I'd like to find a wireless solution where the push of a button would wirelessly close an associated relay in the console. I've looked at commercial solutions and they are all north of $200. Can anyone suggest a circuit that I could use that would be relatively inexpensive and easy to build? I would be willing to consider a commercial solution but, as I said, all the ones I've found so far are out of my price range.

#5132

Pete Schestopol

Atlanta, GA

Please log in to post an answer.

Answers

A solution that worked for me several years ago was to use a wireless doorbell. These generally have a jumper that you can move to avoid interfering with a neighbor that has the same model. You would have to purchase four units and then set each to a different "channel". If your console is not made of metal, you could mount the base units inside the console. Disconnect the speakers if you do not want them to chime. A quick check on Google shows these are available in the $10 to $15 price range. The Honeywell RCWL105A is one that might work for you.

There are both 120VAC and battery operated base units. The push buttons are battery operated in either case. The advantage of the 120 VAC units is that you do not have to purchase batteries and also remember to remove them when not in use. The disadvantage is it may be more difficult to interface these to your console.

I used an AC powered base and added a small 5V relay to provide a contact closure to operate my garage door opener. Note that this will be a momentary contact closure. I could not find a schematic for the unit I used but was able to use an oscilloscope to find a pin that changed state when I pushed the button. The relay takes too much current to be driven directly so I added a FET to act as a low side driver. An optical isolator might also work instead of the relay. These can be driven with only a few mA if the output transistor only has to sink a few mA. BE VERY CAREFUL and don't even attempt to connect an oscilloscope to an AC powered unit unless you have an isolation transformer since these units may operate directly from the 120VAC with no isolation. The relay or optical isolator will provide the isolation once you have found a place to connect it. You can contact me via email at [email protected] if you have questions.

Mark E. Whitmore

Frederick, MD

For wireless control, it is tough to beat the low cost of Sony TV remotes from the local Goodwill, teamed with the IR-D15A 15-Bit Sony® IR Decoder IC from Reynolds Electronics. For RF remote control, there are multiple articles on how to use PIC or Atmel (Arduino) processors using serial communication, simply search or stop by the Microchip site.

An alternate encode/decode is the TX-2/RX-2 "RC car" remote control IC sets available from eBay. Recommend the TX-3/RX-3, and buy in pairs. If using RF instead of infrared, consider the WRL-10535 and WRL-10533 transmitter/receivers from www.sparkfun.com, which I personally use with the TX-2/RX-2 "RC car" set for fan control. The TX-2 can connect directly to an RX-2 for debugging, and it is easy to scope the output. A PIC (16F88) or ATmega32x (Arduino) will probably help for "who clicked first". Holtek also produces inexpensive encoder/decoder pairs. www.allelectronics.com has Sharp IR decoders which work fine with the Sony remotes, AVRs, and much more.

Jim Lacenski

Bellevue, WA

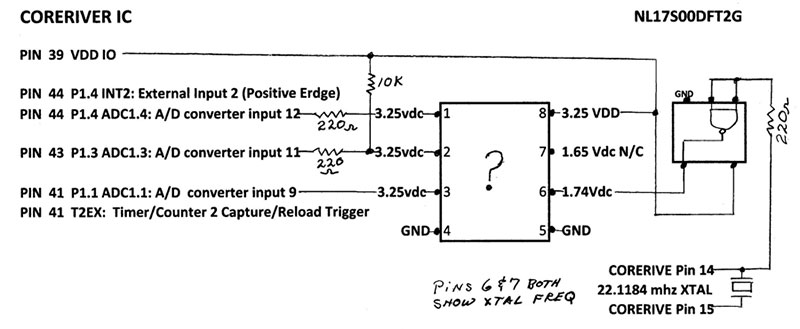

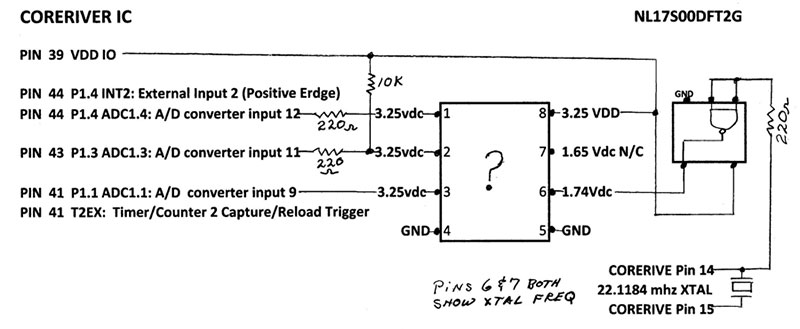

Figure 1 is a schematic I drew of the IC in question. I have not been able to find any IC that would connect in this circuit. There is only a date code on it. Nothing else at all. Pin 6 is obvious, but with pin 5 to ground and pin 7 not connected, I am stumped. The only IC I thought it could be is a serial Flash memory. Any other suggestions?

#5133

Daniel Zielinski

Port Saint Lucie, FL

Please log in to post an answer.

Answers

What about the good old 555 timer IC?

Camillus Blockx

KNOX

I have two Fuji Film digital cameras (FinePix 2650 and FinePix A210). Each came equipped with a 16 MB xD-Picture card (image memory card) which is a semiconductor memory (NAND-type Flash memory) to record digital image data.

I have a micro-SD adapter (orange) with a 1 GB card which fits EXACTLY into the xD-Picture card slot. Even though I formatted the card INSIDE the cameras several times, I'm still getting "Card Error - Card Not Initialized" messages on the camera’s LCD monitors.

Why can't I use this 1 GB micro-SD adapter with these digital cameras? Under what circumstances can I use this type of adapter?

#4131

Don

via email

Please log in to post an answer.

Answers

After reading the question I downloaded the manuals for the two cameras in question. The FinePix 2650 manual shows it capable of using 16 to 128 megabyte memory cards. I'm afraid 8 Gigs is more than a little out of that range. The information is not easy to find in the manual. See page 117.

The FinePix A210 is a little more capable, but not much. On page 79 of the manual for it, the usable memory capacity is listed as 16 to 256 megs.

I have a FinePix AX200 coincidentally with an 8 Gig Micro SDHC card and the adapter that you describe. It works fine. The manual lists number of exposures for cards up to 8 Gig capacity.

This doesn't help you but it does answer your question.

Ron Anderson

via email

The simple answer is that the memory card you are trying to use is too big for the camera[s]. I looked in the manuals available online — the max size allowed is 128 MB for the 2650, and 256 MB for the A210.

Neither camera can handle the 1 GB you're trying to use. You need to find smaller capacity microSD cards. You might try to only format 128 MB [or 256 MB] and see if that works [not sure if you can do that with XD or SD memory cards].

Schneids

via email

You have two problems. The first is SD and XD cards are not interchangeable.

Problem number 2 is the only compatible cards for your cameras per the user manuals are as follows:

FinePix2650

DPC-16 (16 MB)

DPC-64 (64 MB)

DPC-32 (32 MB)

DPC-128 (128 MB)

FinePixA210

DPC-16 (16 MB)

DPC-32 (32 MB)

DPC-64 (64 MB)

DPC-128 (128 MB)

DPC-256 (256 MB)

So, your SD card and adapter will not work, and your cameras will not accept a 1 GB card.

Joe Fulton

Youngstown, OH

What’s the best way to cut a one inch hole in a metal or plastic project box? What about a square hole?

#6132

George F. Powelson

Ogden, UT

Please log in to post an answer.

Answers

The cone shaped step drills work very well for round holes in control panels. If you use a drill press it is very easy to chamfer (debur) both sides of the hole using the start of the next step. You can actually drill it half way from each side if the panel is thicker than the step on the drill.

If you want square or rectangular hole; start with the step drill then use a “nibbler” for the desired shape. Home Depot has the Klein #70611B for about $23. There are several other brands available, including heavy duty and power operated nibblers.

Rhodes Barnette

Henderson, TN

A one-inch round hole can be neatly cut with a step-drill. Many come in sizes that include 1".

Also a chassis punch can be used, although the punches are more expensive. An inexpensive kit of chassis-type punches can be found at Harbor Freight Tools.

Square holes can be cut by drilling inside the corners with a small drill, then cutting between the holes with an emery wheel on a hand rotary tool, such as a Dremel. A file smooths out the cuts. They can also be cut with a "nibbler" if the gauge of the material is thin enough. Nibblers are available from many electronics supply houses that stock tools. RadioShack used to handle them, although I don't know if they still do.

Tom Wilbeck N5KGN

Longview, TX

Go to Greenlee punch and you will find your answer. They have been around a long time, but their punches are rather pricey.

Bob Haskett

via email

While it's virtually impossible to declare a "best" way to do any number of things, I'll share a couple of my favorites.

For cutting round holes in thin materials, it's hard to beat a step drill bit. These are cone shaped cutters that fit in an ordinary drill or drill press and do a great job of cutting or enlarging holes up to about 1.5 inches without mangling the material.

For square holes, I often use a nibbler tool, following up with a file to clean and square up the cut. With a bit of practice you can use the nibbler to cut all sorts of shapes.

James Sweet

via email

The best way to cut a one-inch hole in plastic or metal boxes is to use a chassis punch. Greenlee makes such punches. A one-inch punch is available from Grainger (see www.grainger.com/Grainger/GREENLEE-Round-Knockout-Punch-4A738?Pid=search) as well as many electrical distributors.

Problem is that they're expensive because they're meant for cutting through fairly thick steel. The 1" device from Grainger sells for about $87.

Best bet is to look on eBay for an antique radio chassis punch. At this writing, I found a 1-inch punch offered for under $10 (plus shipping).

Peter Goodwin

Rockport, MA

I would like to make an IR remote control to be used in nursing homes to activate alarm equipment.

Specifications are:

Receiver: nine volt, VERY LOW power consumption

Transmitter:

handheld, battery powered, three volt (lithium?), 2-5 meter range

#6131

Claes Kamborn

Barkarby, SWEDEN

Please log in to post an answer.

Answers

I’m trying to use an SDX01G2 pressure sensor to log CPAP breathing patterns. The circuit uses an LM324N op-amp, an ADC0831 CCN eight-bit A/D converter, and a BASIC Stamp 2 processor. The problem is the sensitivity. The output goes from 0 up to 191, and then back to 0. I have tried several op-amp configurations with little success. I am a newbee, and could sure use some help.

#4133

Henry

Visalia, CA

Please log in to post an answer.

Answers

I would suggest you try using an instrumentation amplifier designed for Wheatstone bridge application. I recommend the INA 125. I would also recommend the TLC2543 12-bit ADC such as used with a Stamp based logger in the following link: [url=http://emesystems.com/OL2tlc2543.htm]http://emesystems.com/OL2tlc2543.htm[/url]

Good luck with your project.

David Erskine

via email

The SDX01G2’s datasheet shows the specs to be rather narrow.

Consider the Freescale MPXV5004 or similar. It’s range (in and out) is far wider than the SensorTechnics model. The 5004 was used in my CPAP project simply because it was a pull from an old CPAP machine.

Terry Meyer

via email

I lost my hearing at a very young age and have always struggled with listening to the audio out of phones, computers, MP3 players, etc. When I have my hearing aids in and try to listen, it’s actually worse!

I would like to build an audio amplifier with a programmable equalizer, to be connected to the 3.5 mm audio output jack. I will connect +5V separately.

The device will be connected to a PC temporarily through the USB jack for programming, and then be removed.

Here are my questions:

Is a one stage amplifier enough?

Is it better to amplify first then equalize, or equalize then amplify?

Who makes the best audio chips?

What software is needed to program the EQ?

Any suggested readings, websites, software, forums, etc.

Specifications:

Easy to build and program using a chip like Monolithic Linear integrated circuit LA3600; www.electronics-lab.com/blog/?tag=equalizer.

Input voltage: 5V

Gain: ?

Equalizer: Seven band or better

Output: 3.5 mm

And for the hard way, using a DSP or FPGA to build an advanced equalizer/gain headset that could be used in any computer, phone, or MP3 player!

#3132

Monito

San Diego, CA

Please log in to post an answer.

Answers

An audio amplifier with a graphic equalizer doesn't require a DSP or FPGA. Quickfilter Technologies (www.quickfiltertech.com) sells a variety of chips aimed specifically at audio applications. The company also has development kits and a neat GUI. No programming needed. A USB cable provides a link between a development board and a PC used to set parameters.

The Quickfilter QF3DFX chip includes a 10-band parametric equalizer and an eight-band graphic equalizer. Cypress Semiconductor's Programmable System on a Chip (PSoC) families (www.cypress.com) include filter blocks, and a graphical drag-and-drop GUI makes it easy to configure a system. These chips include ADCs and DACs, so I bet Monito could create what he wants with only a PSoC chip and a couple of audio amplifier ICs. Find a useful app note at www.cypress.com/?docID=21352, and info about a 10-band graphic equalizer at www.cypress.com/?rID=43672.

Jon Titus

Herriman, UT

If you're generally new to audio processing, I would stick with analog for a while. It's not as cool or widely configurable as a DSP, but it usually does a pretty good job when done right. For your project, you'll probably want:

1. Input gain

2. Three-band or more *parametric* EQ

3. Output gain

4. Power amp

I included two gain stages so that the EQ's working level can be adjusted independently of both the input and output levels. This allows you to overpower the analog noise in that stage without fear of clipping and still get the output level that you want. (Professional analog mixing consoles are basically that on steroids.) The gain stages are the easiest parts of the circuit: Use a dual-gang linear potentiometer (for stereo, single-gang for mono) with an extra resistor between the center-tap and ground. This loading resistor should be roughly 10% to 15% of the pot's resistance, and makes a better audio taper than most audio pots.

The power amp can be a single IC for small speakers or headphones. They're sometimes called power op-amps. The EQ is a little different than I think you had in mind. I think you're imagining a many-band *graphic* EQ, which is easier to understand at first glance, but I think a more useful tool for you would be a *parametric* EQ. Parametric means that you can adjust the frequency of each band, as well as the gain. For example, if you have a problem at, say, 3 kHz, and you have a graphic EQ with adjacent bands at 2.5 kHz and 3.5 kHz, it's going to be hard to adjust that satisfactorily. (This is why professional graphic EQ's have up to 31 bands. Even so, they still don't work well for everything.) With a parametric EQ, you could adjust a frequency knob to put one band exactly where you need it for each problem area. A semi-parametric EQ is easier to build than a full-parametric, and just has the two knobs per band — frequency and gain. A full-parametric EQ has a third knob that adjusts the width of each band. Despite missing a knob though, the semi-parametric version is usually sufficient because it automatically adjusts the bandwidth as a function of gain. Large gain adjustments typically make a narrow spike or notch, while smaller adjustments make a wide hill or valley.

This website (www.sound.au.com) is a great resource for analog audio projects. It has circuits for almost anything you might want to do to your sound, with schematics, detailed descriptions, and usually a PCB for purchase. One minor sticking point for you might be that these circuits are designed for ±15V supplies (30V total, with signals referenced to a center-tap). If all you have is 5V, you might be able to make a switching power supply that provides that, or you might be able to adapt the circuits to run on 5V with a higher noise floor. (Actually, the noise level stays the same, but you're using a smaller signal.)

Aaron Duerksen

via email

I’m just starting in electronics and have taught myself some of the basics through reading books and building kits. I’m intrigued with microcontroller projects and was hoping to get some seasoned opinions on where to start. There seem to be several popular platforms that get most of the attention such as Arduino, PIC, Stamp, Propeller, etc.

Which is best for a beginner?

Can someone recommend a book on programming that assumes zero experience and explains the basics from the start through getting a simple project up and running?

Are there any beginner-friendly online user groups I might join?

Any advice is appreciated.

#1131

J.P.

via email

Please log in to post an answer.

Answers

As a newbie myself, who has tried several approaches, I found one element left unsaid in the answers in the March issue. It really matters what computing platform you use. As a Mac user, I found it very hard to get going with the Parallax or Microchip solutions, since the development systems were extremely PC-centric, so I had to struggle with Boot Camp etc. or get a PC. The Arduino and Atmel platforms were much easier, since the former supports the Mac thoroughly, and everything you could need for the latter can be found at http://www.obdev.at/products/crosspack.

Joe V

via email

I recommend the BASIC Stamp modules from Parallax because newcomers find them easy to use. In addition, Parallax has many books and manuals, as well as kits that get beginners off to a good start. I also like the Arduino Uno because of widespread support from users. The compatible Digilent chipKIT Uno32 provides a more powerful processor and will appeal to people who want to move beyond the eight-bit Atmel chip used in the original Arduino Uno. The kits mentioned use a 5V power source and work with 5V logic devices. Other boards — such as the ARM mbed and BeagleBone — operate from 5V, too, but the I/O pins provide 3.3V logic levels. You might find it difficult to breadboard with 3.3V logic chips, most of which come in surface-mount packages.

Jon Titus

Herriman, UT

Hi. There are a number of ways to get started in mcu's.

In my opinion, Parallax has the best documentation to use for getting started with mcu's. If you do not want to buy their packages, you can download the pdf's and source the parts after looking at the components, which they provide in one nice place in their books. If you use a book such as the StampWorks book, then you should examine the schematics for their Professional Development Board (BS2 version and not the Propeller version) and buy the necessary components to build the experiments. Other BS2 versions are available such as the Stamp Stack II. The "What's a Microcontroller" pdf is also a good starting point.

All the concepts you learn with any mcu system will be able to be applied to any other mcu system. The syntax and instructions will vary but the concepts remain the same. Arduino has a number of books written about it and is probably the most popular among those who know little about mcu's. It was made with artists and builders in mind, not for engineers and tech-like people. They have done a good job of marketing and there are many applications made accessible through their "shield" format. Of course, there are quite a few books written about Arduino and you should examine whichever book to find out what parts you will need to work with the projects.

The PICAxe is also fairly popular and is programmed in a version of BASIC. The Propeller is supposed to be a little more advanced as are AVRs, PICs, and other major companies’ mcu's that are mostly programmed in C. For a beginner, I would stay away from the Propeller, AVRs, and PICs as there will probably be too steep a learning curve. The Basic Stamp 2 is a little more expensive as you will need the mcu and, if it is not a USB version, you will also need a USB-to-RS232 converter, unless you have a PC with the old serial port, DB9 style.

The Arduino is cheaper and more popular but you will most likely have to do a little more searching and trial and error to get your code running with the documentation available. Parallax, the company that makes the BS2, has very good documentation. Another advantage that the Arduino has, is that programs written in C/C++ will also work in the Arduino environment.

Books for the BS2: "What's a Microcontroller?" and "StampWorks."

Books for Arduino: the Evil Genius books and probably "Arduino Cookbook."

Books for the PICAxe: Unknown but there are bound to be some on the PICAxe homepage as well as Amazon.

Kits are available from many suppliers. Have a look online for some of these, but the list is not exhaustive: Parallax, Solarbotics, RobotShop, Digikey, ABRA Electronics, Sparkfun, Adafruit Industries, and Make. Be sure to check the websites thoroughly as some also have tutorials as well as documentation on their products.

Bruce Fleming

New Glasgow, Nova Scotia

Hi J.P.

I am also at a similar beginning stage as you describe. I am currently working through a book called "C Programming for Embedded Microcontrollers" by Warwick A. Smith, which I find thus far to be excellent. The ISBN is 978-0-905705-80-4.

Here are the books features:

-

Use only free or open source software.

-

Learn how to download, set up and use free C programming tools.

-

Start learning the C language to write simple PC programs before tackling embedded programming - No need to buy an embedded system right away!

-

Start learning to program from the very first chapter with simple programs and slowly build from there. No programming experience is necessary!

-

Learn by doing - Type and run the example programs and exercises, which can be downloaded from the Internet. - A fun way to learn the C programming language.

-

Ideal for electronic hobbyists, students and engineers wanting to learn the C programming language in an embedded environment on ARM microcontrollers.

As a beginner, I personally found Arduino to be the easiest platform to get a running start.

Agg

via email

I'm looking for a schematic for a Dish Network satellite receiver model DISH311. The audio is too low and I'm wondering if there was any adjustment that could be made to increase it.

#2133

Wayne Carpenter

Omak, WA

Please log in to post an answer.

Is there a way to operate my home X10 devices using my iPhone through my Wi-Fi network (preferred) or Bluetooth?

#1132

Anton Stamos

Scottsdale, AZ

Please log in to post an answer.

Answers

Try the Insteon hub. It gives you smartphone and web access to your Insteon and X-10 modules at home or away, plus text alerts from sensors, if you install them. It’s a free app and there are no fees. Or, use the Smartlinc unit — an older version of the above — except no text alerts.

Mike Carland

Santa Clarita, CA